IMA News

Since 2018, we at IMA Dresden have been a partner in the @CarE_Service_EU project funded by the European Commission. The aim is to develop new and environmentally friendly car sharing and integrated mobility services. The focus is on the future of European mobility and the associated improvement of citizens' quality of life. But acceptance is not yet 100% guaranteed: There is uncertainty about the introduction of electric mobility and although the potential of car sharing is huge, it has been underused so far. The project is now conducting a survey so that the social impact of the new mobility services can be assessed. Agents need the opinion of future users to determine the final design and implementation of the service. So here is our request: [...]

Read more

The 18th International Rail Vehicle Conference will take place in Dresden from 22-24 September 2021. The conference, organised by HTW Dresden, TU Dresden and DDV Media Group, has been held every one and a half years since 1996. Topics of the symposium are, for example, new drives, digitalisation and innovations in the field of rail vehicles. IMA Dresden will be represented at stand 7. Dr. Thorsten Voigt, Prof. Roland Rennert and Dipl.-Ing. Franz Ellmer from IMA Dresden will be there. We look forward to seeing you! [...]

Read more

It's that time again: Europe's second largest railway technology trade fair will take place for the 13th time on the Polish Baltic coast in Gdansk from 21-24 September 2021. IMA Dresden will of course be part of it. The Saxony Economic Development Corporation has organised a joint stand under the umbrella brand "Saxony live". You will find us there in Hall E at number 24. We are very much looking forward to your visit to our stand! [...]

Read more

This is how team spirit at IMA Dresden looks like! In total four teams have mastered the Rewe Team Challenge Dresden 2021.

On September 1st, the teams “IMA Runners”, the “Imaner” and the “Kriechversuch” (creep test) set out on the five-kilometer route.

On the second day, the team "Die Oktopoden" (The octopods) took part.

We congratulate our teams on this great achievement!

[...]

We are happy to welcome new colleagues at IMA Dresden.

Two young people start their apprenticeship today on September 1st.

We bid a wonderful start to:

- Elisabeth Scheel - material tester metal technology

- Vincent Schwandt - industrial mechanic

Additionally, we offer internships and a one-day to three-days trial period for interested people.

Alongside our experienced team members, you’ll get to know us and our work. Please contact us! [...] Read more

Regional air traffic of the future has to be sustainable, as silent as possible and low in emissions. As an innovative, accredited test centre and certification body, IMA Dresden is part of a consortium that plans to build an aircraft for the requirements and generations to come: the so-called “Silent Air Taxi E-SATstart”, shortly named “E-SATs”. The silent “E-SATs”, which will be driven by a parallel hybrid system, is being developed by RWTH Aachen University, TU Hamburg in cooperation with eight technology companies. The task of IMA Dresden is to carry out structural tests in cooperation with the Institute for Textile Technology. The test results should lead to the production of a prototype for the wing construction: the criteria [...]

Read more

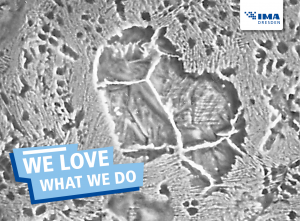

We love what we do! Not surprisingly at all that this love shows under the scanning electron microscope. Our experts in the materialography laboratories were so happy about this beautiful surprise. Clearly, at IMA Dresden, the passion for testing materials is just not superficial. In our accredited materialography laboratories, we examine both, metallic and non-metallic materials of different compositions to determine and evaluate the state and quality. High-resolution imaging techniques enable us to see things normally hidden to the human eye. Read more here: Materialography [...]

Read more

When does material fatigue occur in hip, knee, elbow or vertebral implants? At IMA Dresden, ten testing machines are busy answering these questions. Only recently, they have been modernized to state-of-the-art. We retrofitted them to servo-hydraulic drive system and installed a new measuring and control system for optimized accuracy and improved process reliability. As an accredited and recognized testing laboratory (DIN EN ISO/IEC 17025:2018) for medical device testing, we support manufacturers, physicians and other experts in the field of approval testing, failure analysis as well as research and development of medical devices. The tests are carried out according to standard test methods, such as ISO 7206-2, -4, ASTM F1800 and ASTM F1875, [...]

Read more

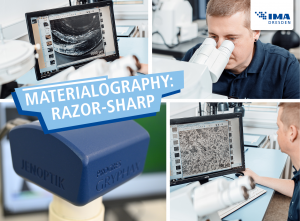

Razor-sharp: Our materialography lab features new Progress Gryphax®ARKTUR cameras from Jenoptik and suitable software from Imagic for macroscopic and microscopic uses. Our customers now benefit from quality images and micrographs. In parallel, the modern image management system and new options, such as automatically generated reports, improve and facilitate our internal processes. This new acquisition is an investment in the high quality that we stand for as IMA Dresden. Learn more about the materialography laboratory at IMA: https://www.ima-dresden.de/leistungen/werkstoffe/materialographie/ [...]

Read more

IMA Dresden has done its first wear test for ankle joint implants in accordance with ISO 22622:2019 and thus expanded the test portfolio in the field of medical devices at the same time. The implants have to withstand five million cycles in level walking load profile. The ankle implants are tested in the wear simulator, which has two four-station test benches. Two standard wear tests can be conducted simultaneously, i.e. three wear couplings plus one loaded reference coupling each. The IMA wear simulator can run in displacement and force control mode depending on test requirements. We are proud of our engineers in the department of medical device testing and thank Marcel Langner, Robert Paul, Frank Gatzke and Sebastian Fuchs for the realization [...]

Read more