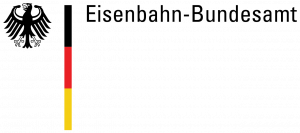

Construction Product Testing

IMA Dresden plays a leading role in the field of construction products.

As an independent, recognized and accredited testing facility and inspection agency, it assists manufacturers, operators, suppliers and experts with all aspects related to product compliance, life cycle, condition assessment, material characterization, quality and safety standards.

Along with the material testing of all metals, plastics, fiber composites and even textile-reinforced concrete, we offer a range of approval and initial tests, monitoring and installation inspection, in addition to construction acceptance. Statement related to the strength of the material, service life, damage behavior and ageing are also generated.

Read brochure Test mark database Test mark database

Surveillance and certification body according to state building regulations Search for standards

Our portfolio

We can advise you well.

IMA Dresden is based on the globalization and therefore we are able to guide you through national and international requirements, testing processes and specifications of the applicable standards, regulations and laws.

Please accept functionality cookies to display content.

All in one hand with IMA Dresden.

With our accreditations and recognitions, we support manufacturers, distributors, construction planners and contractors.

TESTING BODY | INSPECTION BODY | CERTIFICATION BODY |

|

|

|

|

|

|  |

Therefore, we are entitled to issue both certificates of conformity (LBO, EBA) and certificates on constancy of performance and product conformity (EU-BauPVO).

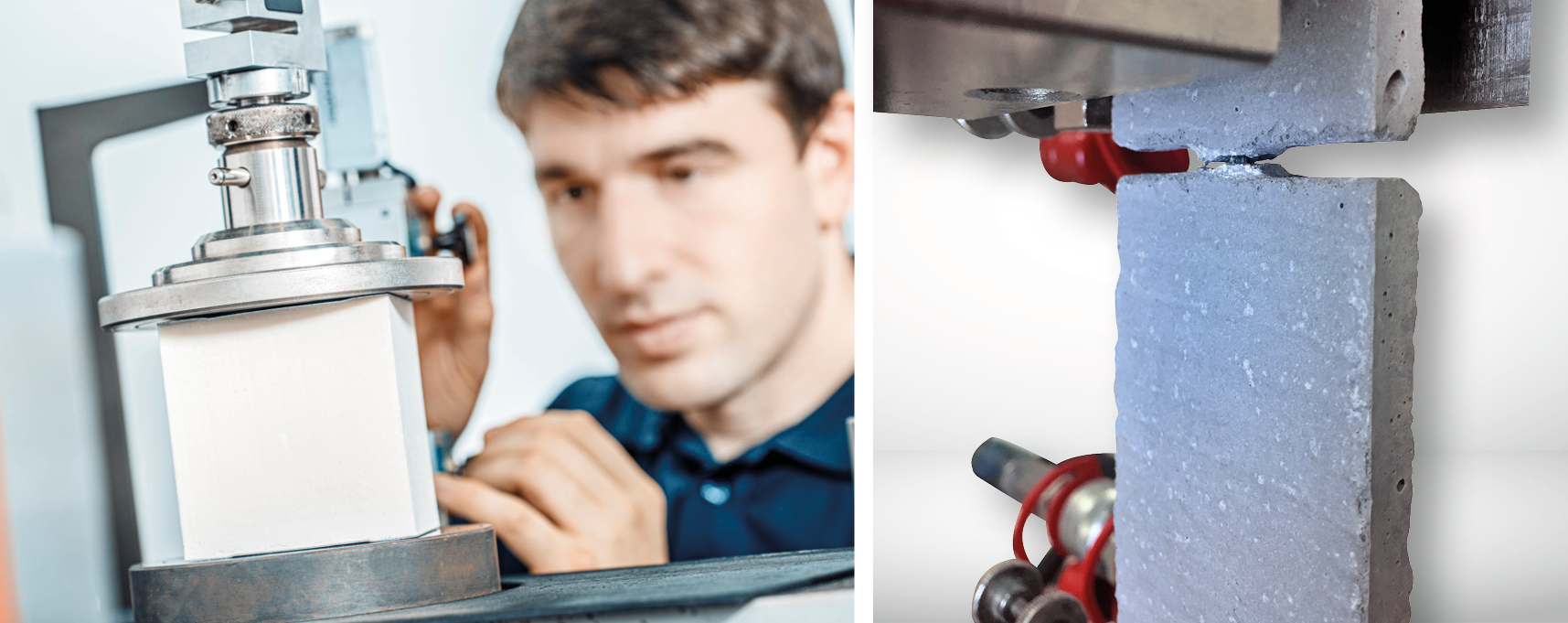

OUR TEST AREAS FOR BUILDING PRODCUTS

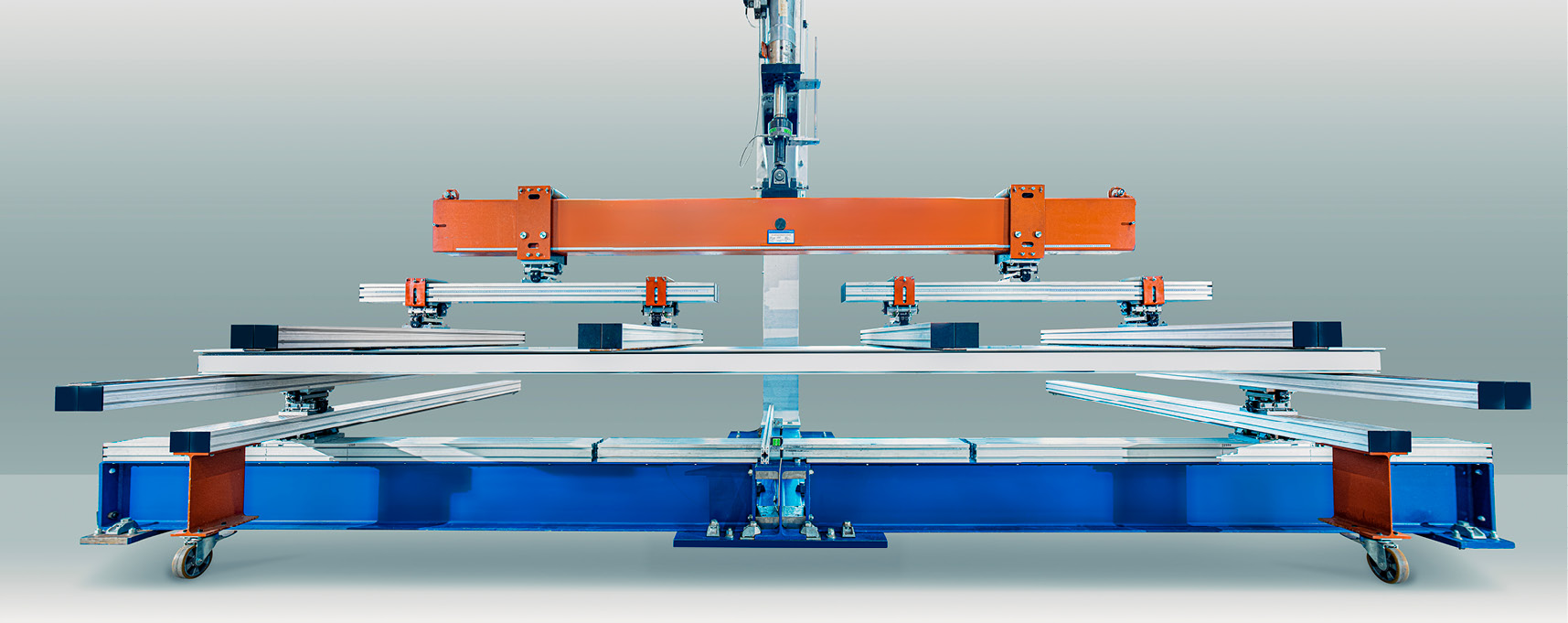

With our testing technology and engineering knowledge, we cover the testing of the following wide-ranging construction product groups. There are no limits. We adapt our test stands and qualifications to your innovations.

- Sandwich panel

- GFRP construction profile

- GFRP grating

- Metal sheet profiles (trapezoidal profile, standing seam profile, cassette profile, sidings, corrugated profiles)

- components made of thermoplastics, composites and glass-fiber reinforced plastics (GRP)

- Reinforcing textile, textile concrete

- Reinforcing bars made of glass-fiber reinforced plastic (GRP)

- pure resin systems

PrODUCT AND APPROVAL TESTING

You can depend on us to finish your work. As part of our job, we carry out product testing all the way to final certification. Both for tests that are legally required for market approval and for optional tests.

Our testing portfolio

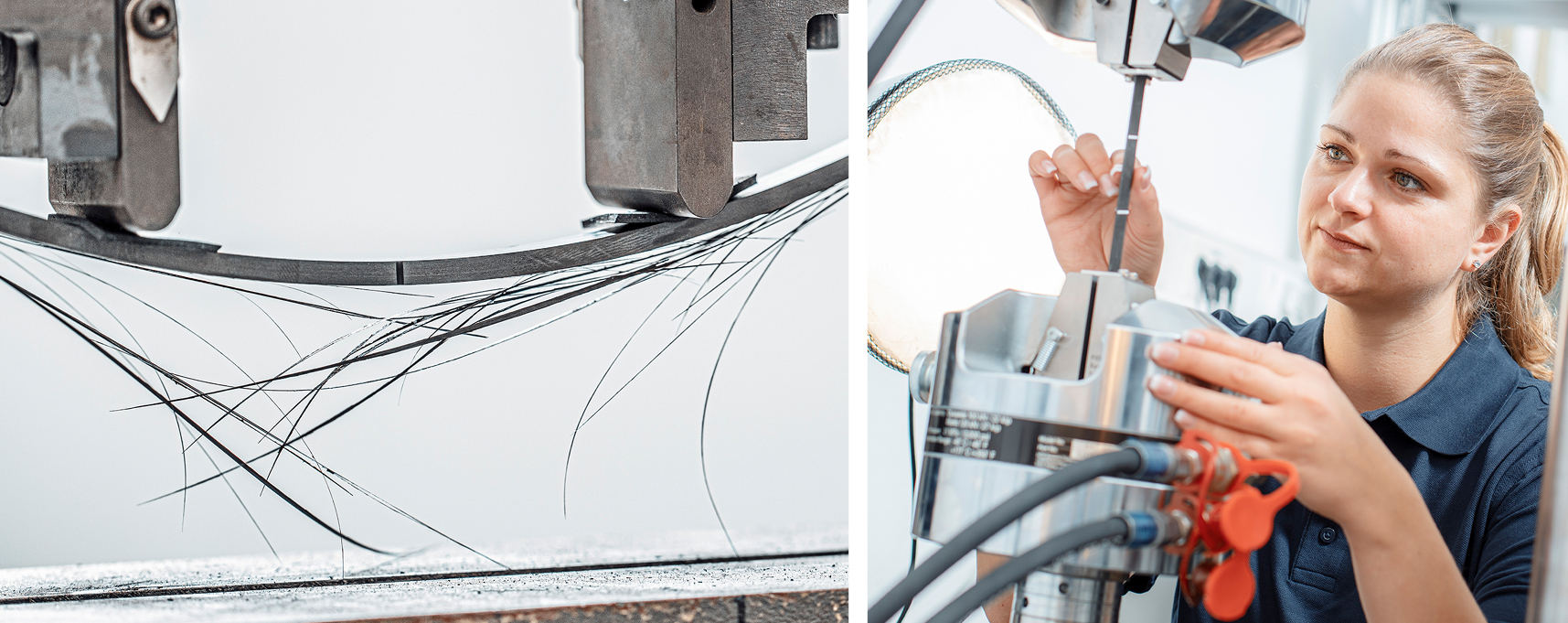

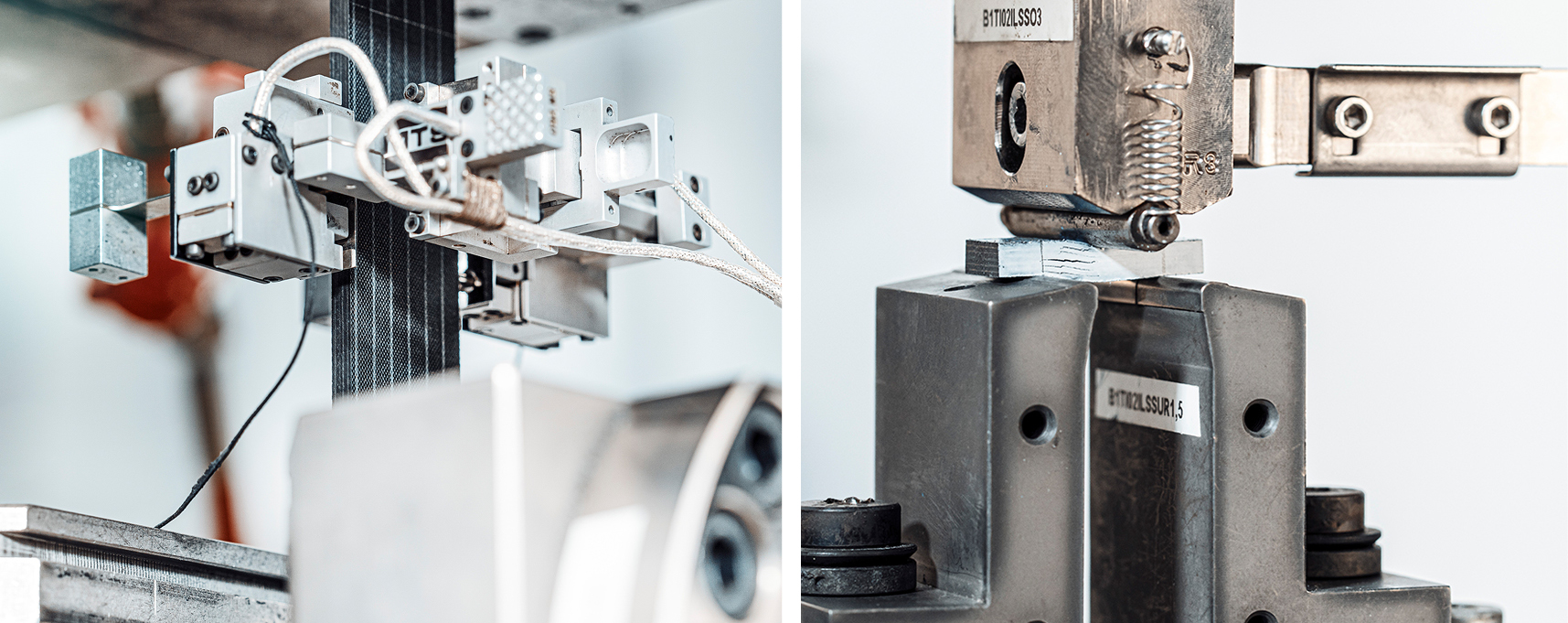

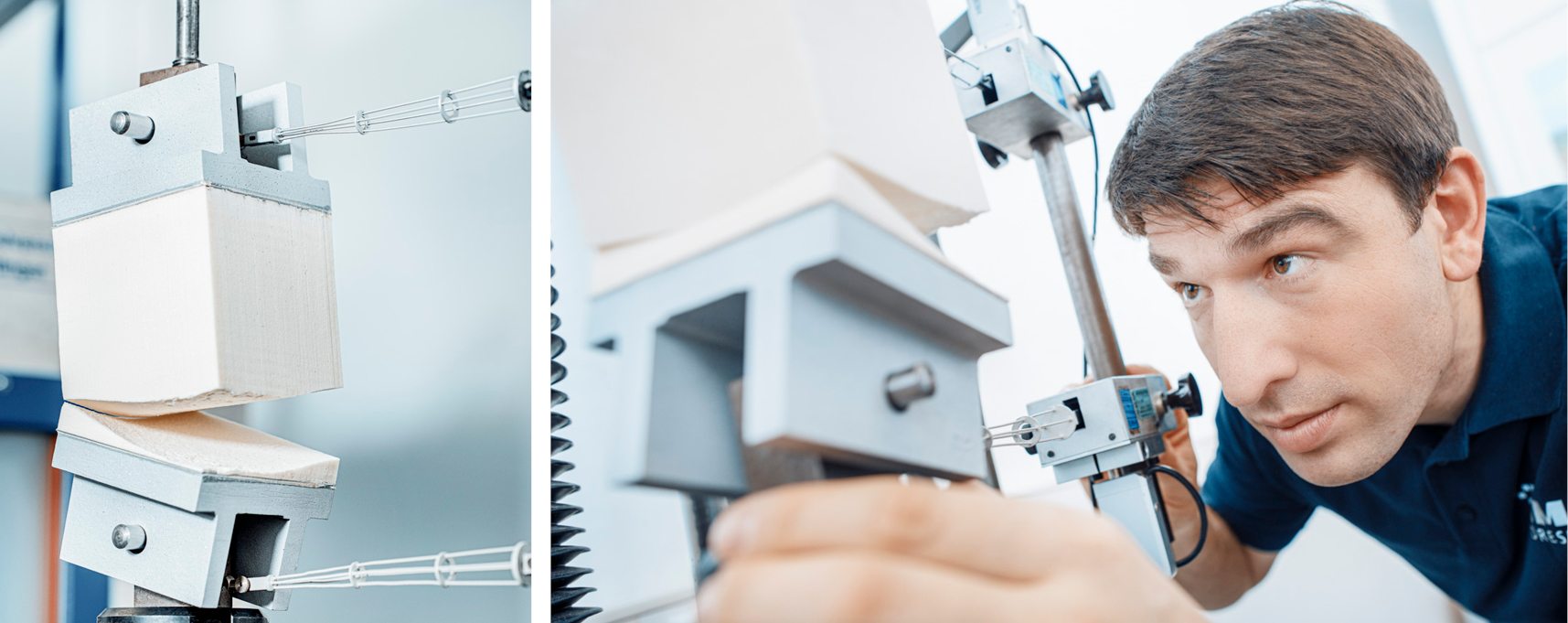

- Mechanical and physical testing of materials and components

- Mechanical testing of fastening systems

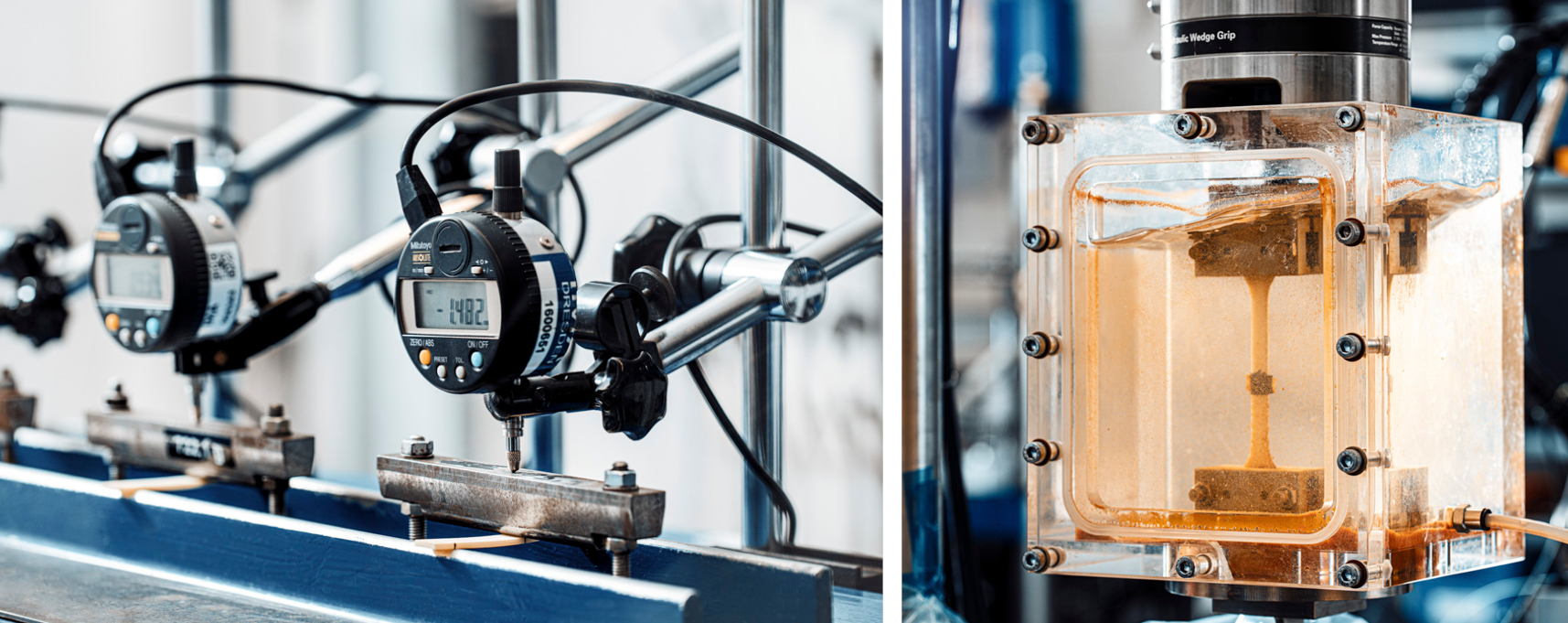

- Material Creep testing

- Long-term testing, durability

- Environmental simulation

- Ageing test

- Thermal conductivity

INITIAL MONITORING AND PRODUCT CERTIFICATION, EXTERNAL MONITORING AND INSPECTION

As a manufacturer of products subject to approval in the construction industry, it may be mandatory for you to have the factory production control by an independent, recognized and accredited monitoring or inspection body.

Our services

- Initial inspection of your factory and review of the factory production control (FPC) orRegular inspection and assessment of the factory and the FPC

- Sampling for the initial test

- Characterization of the properties of your materials, semi-finished products or components

- Comparison of the results with the requirement values for approval

- Transmission of the inspection and test results to the relevant certification body

- In case of confirmed conformity or compliance: Issue of a certificate of conformity

- External monitoring for regular inspection of the factory production control (FPC) on the basis of the technical specifications

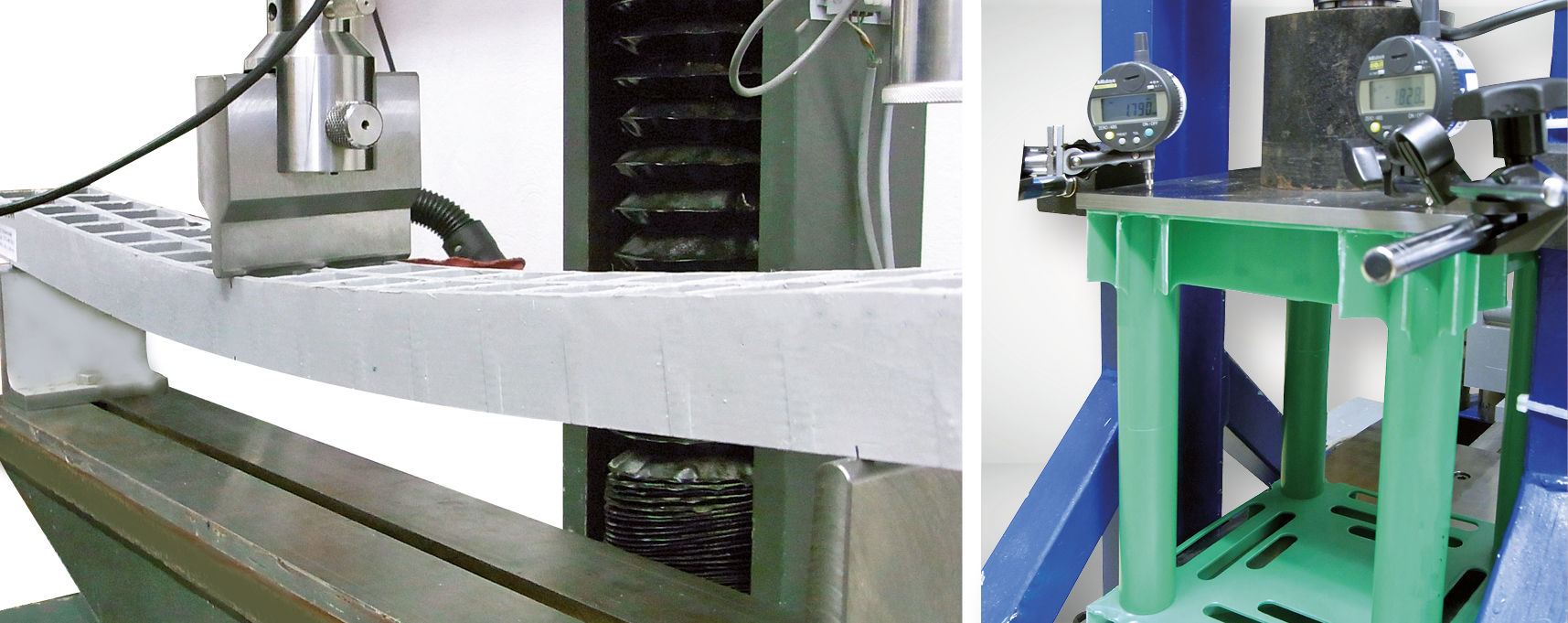

MATERIAL TESTING

We can execute material tests and produce samples as well as laminates such as plastics, composites, metals and textile concrete.

Do you have concerns about test programs, planning or evaluation of the result? We are more than pleased to assist all of your questions.

Our expertise

- Specimen manufacturing

- Physical testing

- Static mechanical material testing

- Material long-term testing (creep, creep rupture)

- Chemical resistance

Read more here: MATERIAL TESTING FOR PLASTICS AND COMPOSITE MATERIALS

OUR ACCREDITATION AND RECOGNITIONS

With several accreditations and recognitions, IMA Dresden has demonstrated competence, independence and performance.

Accreditation of testing laboratories

All of the testing laboratories are accredited according to DIN EN ISO/IEC 17025. Flexible accreditation allows us to test materials and components according to different standards, as well as developing new testing procedures.

DAkkS-accredited inspection body

For many years, IMA Dresden has been recognized by Deutsche Akkreditierungsstelle GmbH (DAkkS) as an accredited Type A inspection body in accordance with DIN EN ISO/IEC 17020.

This includes the inspection of plastic or plastic composite components in structural and civil engineering.

DAkkS-accredited certification body

For many years, IMA Dresden has been recognised by Deutsche Akkreditierungsstelle GmbH (DAkkS) as an accredited certification body in accordance with DIN EN ISO/IEC 17065.

This applies to the certification of pipes and pipework systems for water and gas supply and wastewater disposal, as well as sandwich elements and glass fiber-reinforced plastic (GRP) construction profiles.

Application for certification for construction products // Application for certification according to the Construction Products Regulation

Please send the completed forms to: ima-cert(at)ima-dresden.de

Are you interested in checking the validity of your certificate?

Don’t hesitate to drop us an Email to ima-cert(at)ima-dresden.de with the name of the certificate holder or the certificate number.

We will check your request and send you the certificate as soon as possible.

Monitoring and certification body in accordance with the German state building regulations

IMA Dresden is accredited by the Deutsches Institut für Bautechnik (DIBt) as a monitoring and certification body in accordance with the state building regulations for the construction products listed in the notice in the regulated and non-regulated spheres (SAC 08).

Application for certification according to state building regulations

Please send the completed forms to ima-cert(at)ima-dresden.de

Federal Railway Authority testing, monitoring and certification body

The German Railway Authority (Eisenbahn-Bundesamt, EBA) has confirmed the DIBt’s approval of IMA Dresden as a monitoring and certification body for railway-specific construction products, construction types, components and construction methods.

PPA-Europe testing and monitoring body

IMA Dresden is recognized by Panels and Profiles Europe (PPA Europe) as a testing and monitoring (“third-party”) body for sandwich elements and sheet metal profiles.

Ima Test Mark

The test mark of IMA Dresden gives you a recognised seal of quality for your products and manufacturing process. In addition, we award the IMA certification mark based on technical specifications to assess product compliance. Independent inspections and monitoring by IMA prove the quality of your products. The IMA Dresden is accredited and recognised by numerous bodies, thus serving as a distinction for your products.Upon request, we can provide all customers with the IMA test mark and the IMA certification mark, provided that testing/monitoring has shown that the requirements of the standard or regulations in question are being met. The rules for awarding the mark are set out in the testing regulations. You can use the logo for advertising and labelling purposes.