Materials testing of metallic

Materials and compounds

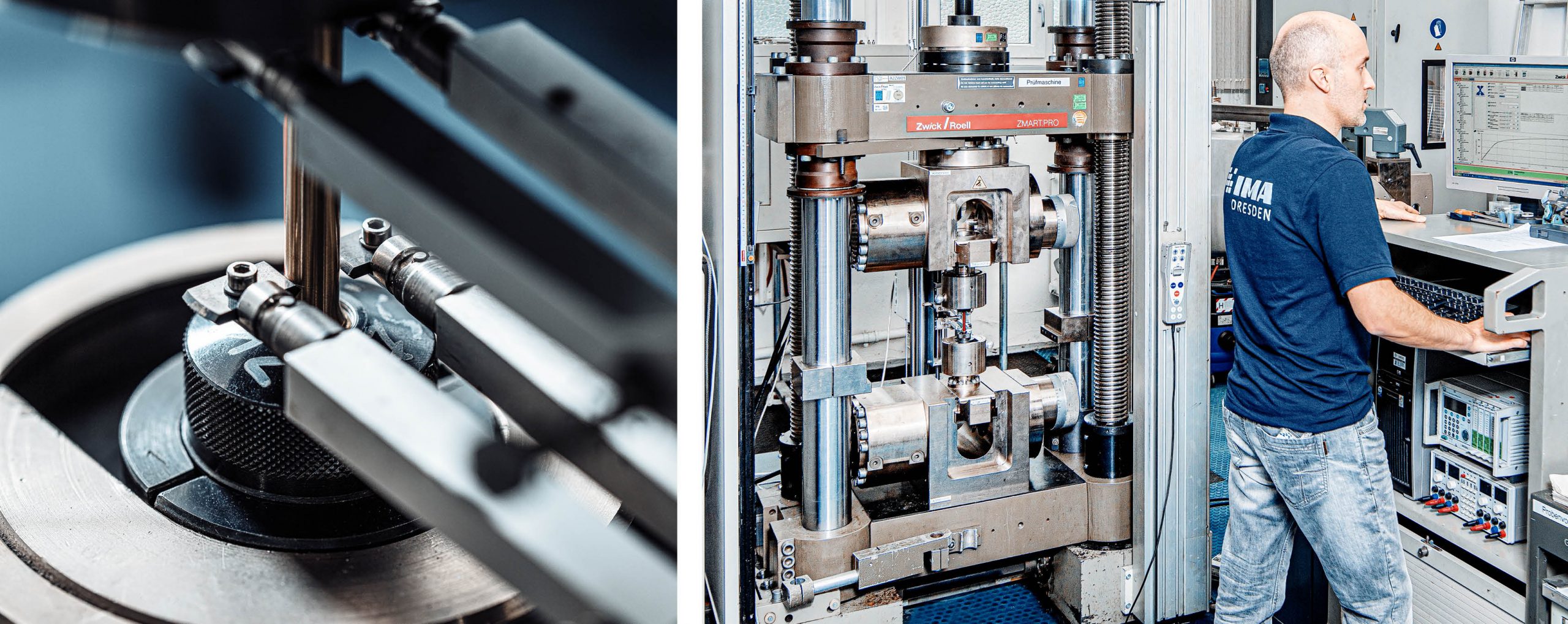

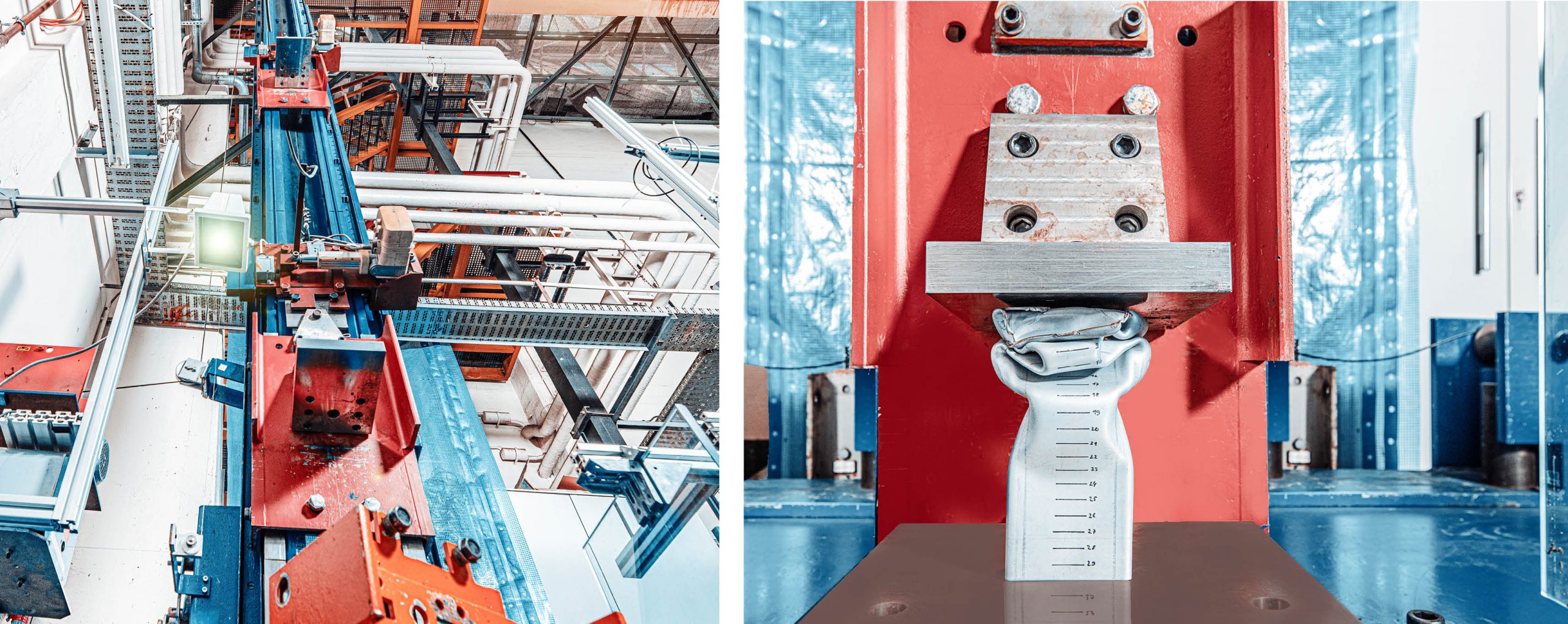

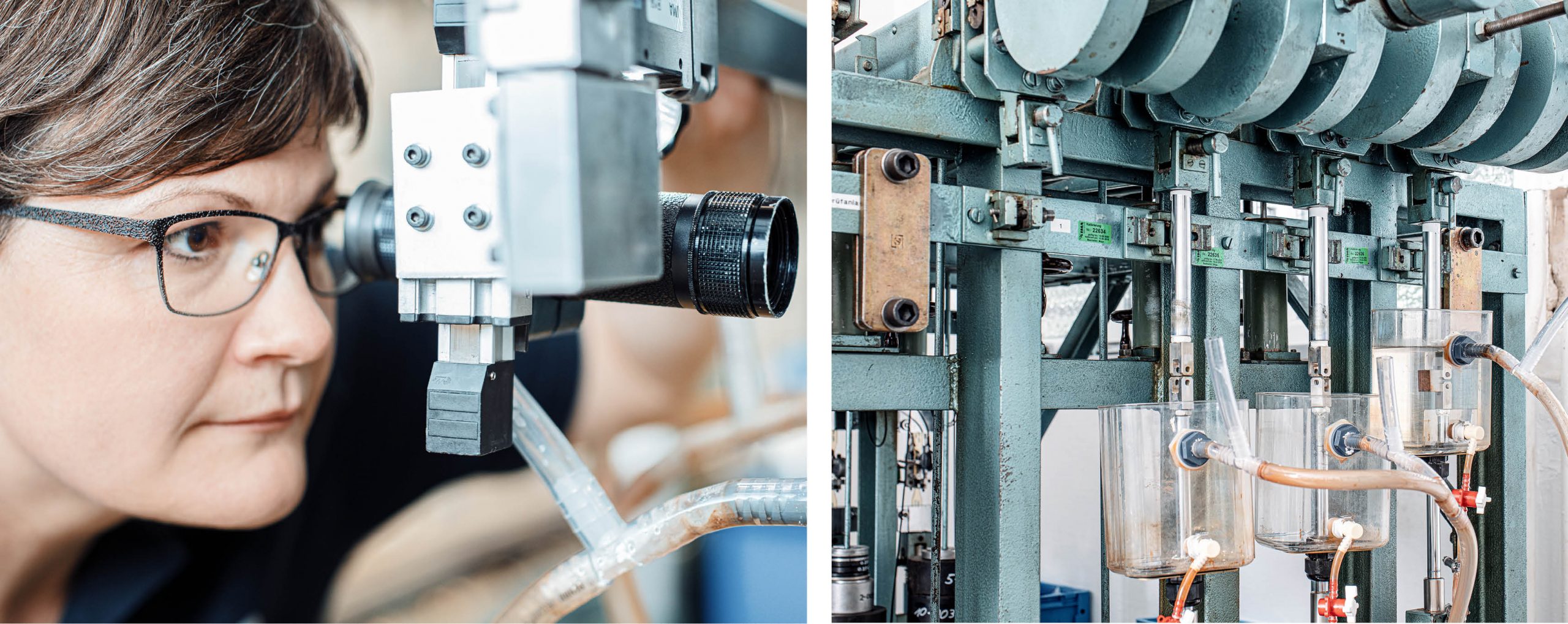

IMA Dresden is an international test service provider for material testing and component testing.

As a manufacturer or processor of materials, we will provide you with comprehensive engineering

expertise regarding resistance, strength and reliability studies on standardised samples up to, and

including, complex components. Verifying the reliability and safety of the material for the service life

of a component with a wide variety of types of load is a demanding task – for us it is a core competence.

Positioned between research and industry, we dedicate ourselves, for example, to face Questions about

the crack propagation behaviour with regard to lightweight construction materials or the comparative

characteristic profile of parts made from additive and conventional manufacturing.

Our engineers will be pleased to support you during the implementation for your testing programs as

well as assisting with the standardisation, approval and certification of materials or manufacturing processes.

We are also available to assist you throughout the entire testing process. Starting with consulting, test

planning and manufacturing samples through to testing and on to the finished test report and supporting

you moreover with the optimisation process. The test spectrum of our accredited laboratories covers

all industrial sectors.

We work according to German and international standards and guidelines (DIN, ASTM, ISO, etc.),

or in accordance with factory settings. Our test laboratories are accredited according to

DIN EN ISO/IEC 17025 for mechanical and technological testing and moreover are accredited for

the business fields of “Material Testing of Metallic Materials” and “Material Testing of non-metallic

materials according to SAE Aerospace Standard AS7003 by NADCAP” (National Aerospace and Defence

Contractors Accreditation Programme).

Our portfolio

Investigation of the material properties

We assume the comprehensive determination for your material parameters as well as evaluating the

loading capacity of metallic materials, jointed connections or hybrid material combinations.

Depending on requirements or specifications involved, tests can be executed at lower and higher

temperatures as well as media influence supported. We provide comprehensive standard testing and

measuring equipment for material and component testing.

You can also benefit from our years of experience in design and application of special test rigs.

Please contact us if you Need a customized solution for your testing requirements. Our experienced

engineers are at your disposal for advice. The preparatory discussions are of course free of charge.

MECHANICAL-TECHNOLOGICAL TESTS

At the beginning of a design phase, the question of the choice of material selection is raised comes to the fore.

The selected material forms a basis and must withstand a wide variety of the most diverse and complex stresses

in later use. Materials testing offers you the an ideal basis for determining the material performance capacity

that the material must have provide for your project.

Standards

Here you can find the standards of mechanical-technological tests.

- Tensile test

- Compression test

- Fatigue testing

- Bending test

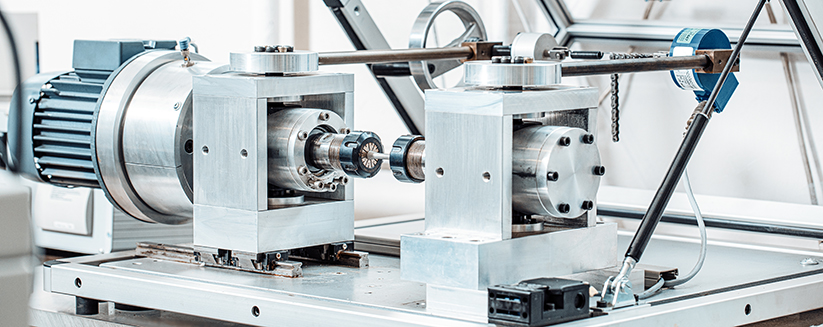

- Fatigue testing (Rotating bending test)

- High danymic load (Impact/ crash test), Charpy impact test

- Stress rupture test

- Strain ratio test

- Impact strength

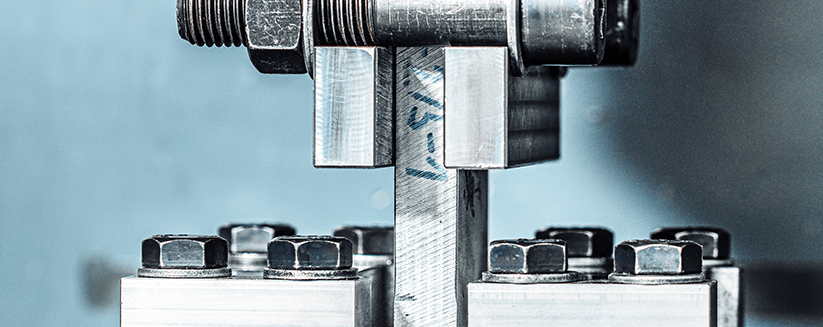

Testing under static loading

- Tensile test

- Fracture mechanics / fracture toughness

- Compression test

- Bending test

- Torsion test

- Shear test

- Stress rupture test

- Bearing test

- Hardness test (Brinell, Knopp, Rockwell, Vickers, UCI)

Testing under cyclic loading

- Fatigue test

- High Cycle Fatigue (HCF)

- Low Cycle Fatigue (LCF)

- Thermal-Mechanical Fatigue (TMF)

- Determination of cyclic deformation curves

- Determination of Wöhler curves (S-N Curves)

- Fracture mechanics / determination of fatigue crack growth rates and threshold value

Impact load testing

- Notched-bar impact bending test

- Pellini test

- Impact / Crash Testing

Our laboratory provides modern equipment for the increasingly important investigations of energy absorption

and crash behavior. In addition to the determination of characteristic values under quasi-static load, we also

carry out tests under dynamic load for you.

Drop weight test

- Drop weight mass: ≤ 200 kg

- Maximum working capacity: ≤ 19 600 J

- Maximum impact velocity: ≤ 18.3 m/s (66 km/h)

- Drop weight with 3-channel registration of the force signals

- 200 kHz sampling rate per channel

- Incident times up to 650 ms

- 6-channel strain and elongation measurement with strain gauges

- High-speed digital camera with video optical plastic deformation measuring

- Standard image rate 4000 f/s

Time-related progressions for force, distance, speed and acceleration can be measured or calculated.

The available testing equipment enables static residual strength tests (strength tests) to be executed

subsequently after impact damage.

Drop test towers

- Maximum impact energy: 400 J

- Impact speed: 9 m/s

- Variable sample geometries testable

Testing of Surface

- Profilometry

- Measurement of roughness characteristics

Technological testing

- Testing of fasteners

- Soldered, brazed and welded joints

- Riveted and adhesive bonded joints

- Testing of parts and components

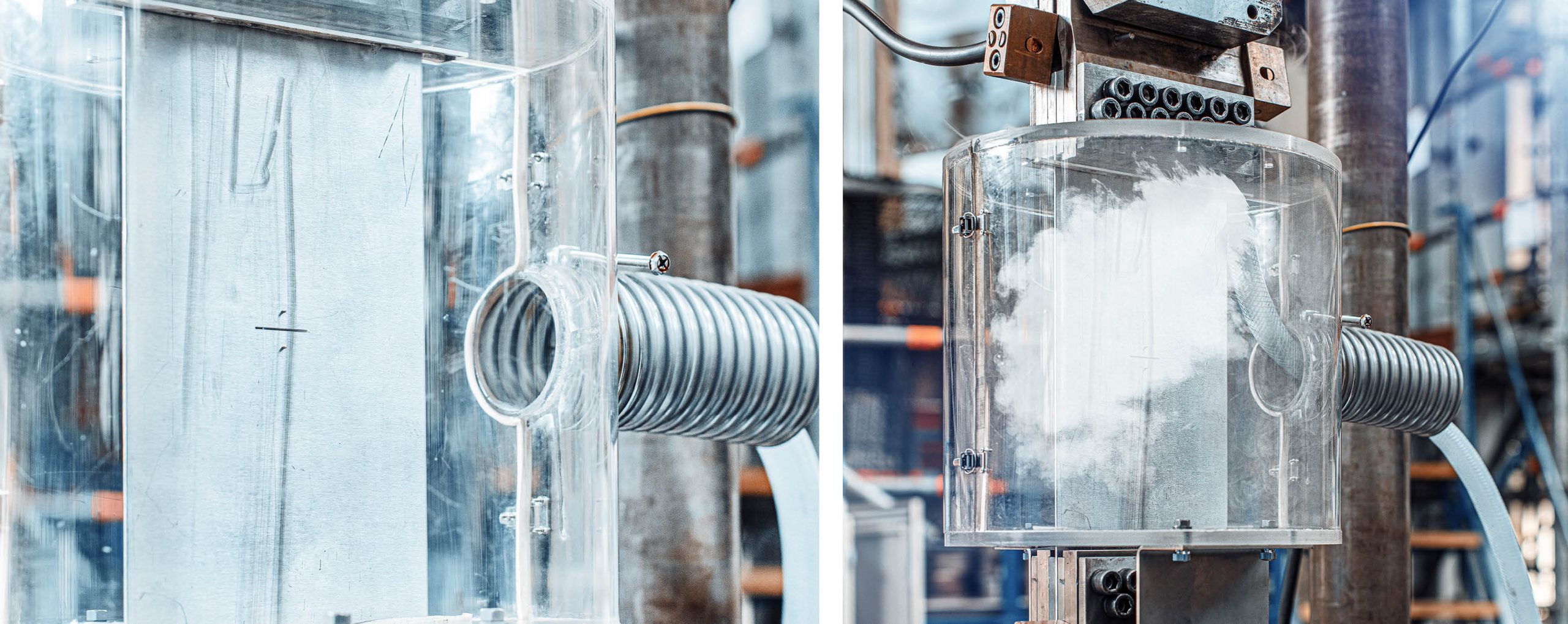

Thermal-mechanical fatigue tests (TMF)

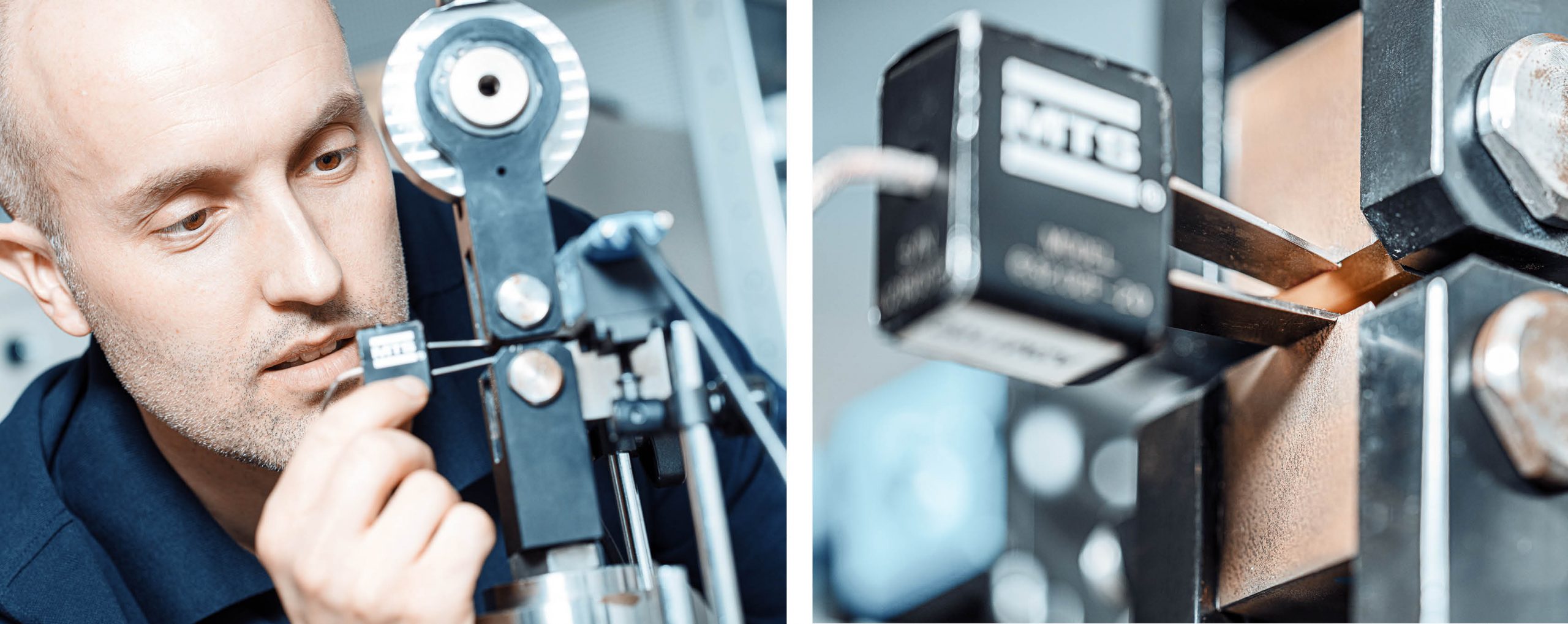

Our laboratory is equipped with higher-level state-of-the-art technology for investigating the Fatigue

behaviour under mechanical loads with simultaneously accompanying thermal load profiles.

Implementation of the tests will be executed in accordance with the internationally recognised

“Code of Practice for Strain Controlled Thermal-mechanical Fatigue Testing”.

- Servo hydraulic universal testing machinery

- High-temperature strain and elongation transducer

- Maximum force: +- 100 kN (dynamic)

- Test frame: +- 250 kN

- Temperature range: up to 1200°C

- Usable space diameter/usable space height: 60 mm/120 mm

- Usable space diameter/usable space height: 24 mm/150 mm

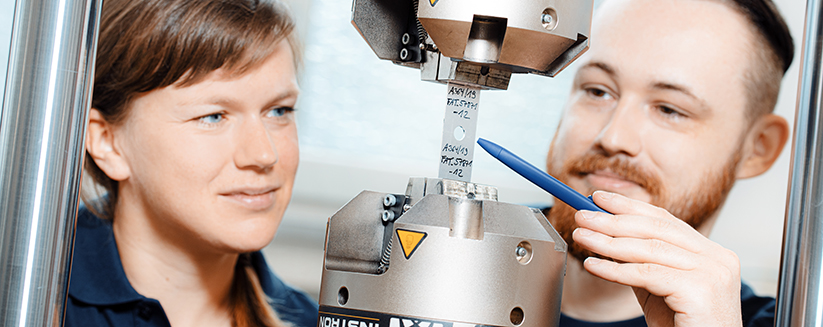

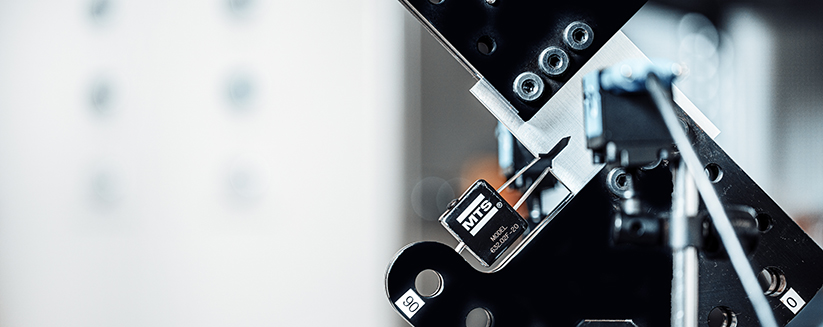

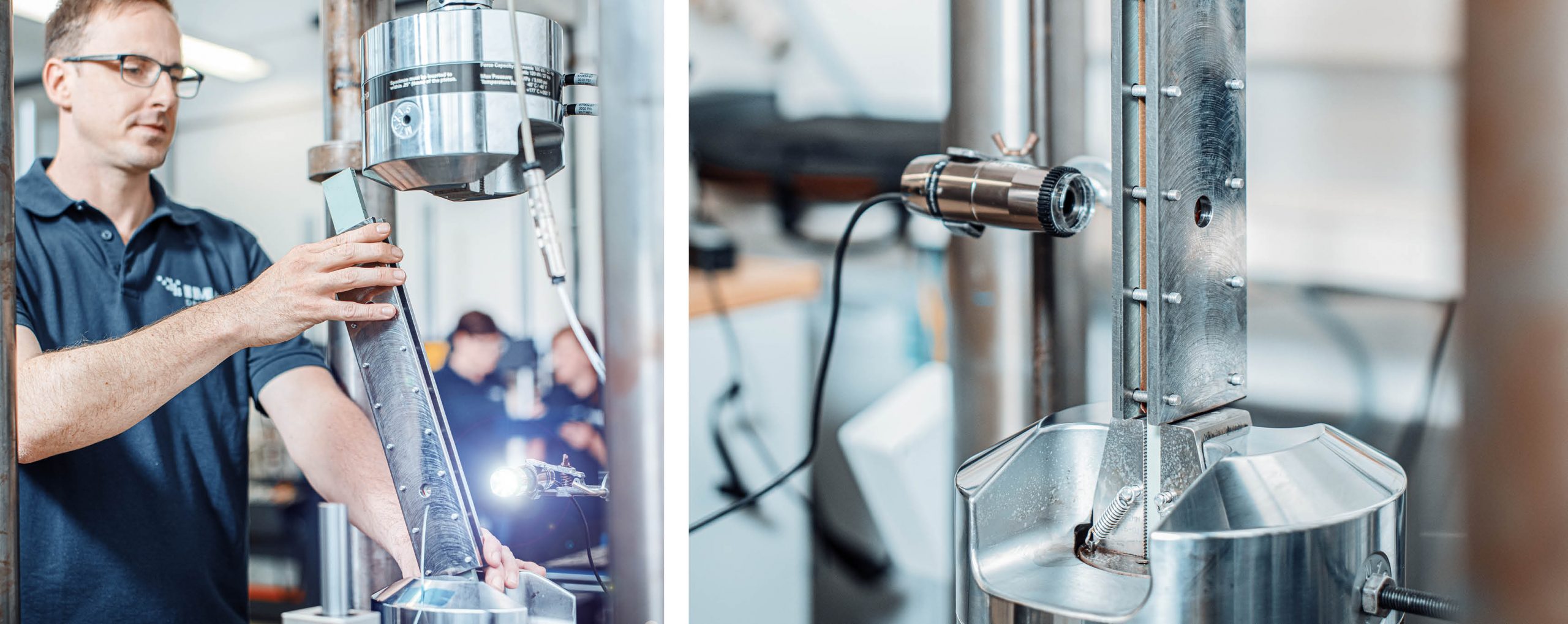

Fracture mechanical testing

In general fracture mechanical investigations enable a quantitative description of the material damage

behavior caused by crack initiation and crack propagation by means of continuum mechanical failure analyses.

In order to fully exploit the potential of new or already existing engineering materials, it is necessary to apply

already existing calculation and testing methods or to develop new testing methods which can represent the

behavior of a component under real-time operating loads and stresses to the greatest possible extent and

ensure sufficient safety against the various possibilities of failure.. Especially in view of the increasing safety

requirements, but also with regard to the economic efficiency and conservation of resources, an exclusive

design of components and structures on the basis of classical science of strength of materials

(i.e. without considering defects in the material or component) is no longer up-to-date.

On the contrary, cracks which could occur either as a result of the manufacturing process or by stress or

during operation must be considered in the design. The evaluation of cracks and/or crack-like imperfections

in construction parts and components is indispensable for determination of fracture mechanical parameters

such as, for example, the threshold value behavior or the crack resistance behavior as the fracture mechanical

analysis of fictional and real existing cracks must be increasingly considered as an additional safety factor

in the component design process.

Standards

Standards overview in the field of fracture mechanics testing.

- Fatigue crack growth rate testing

- Crack resistance curve

- Determination of fracture toughness

- cyclic crack propagation

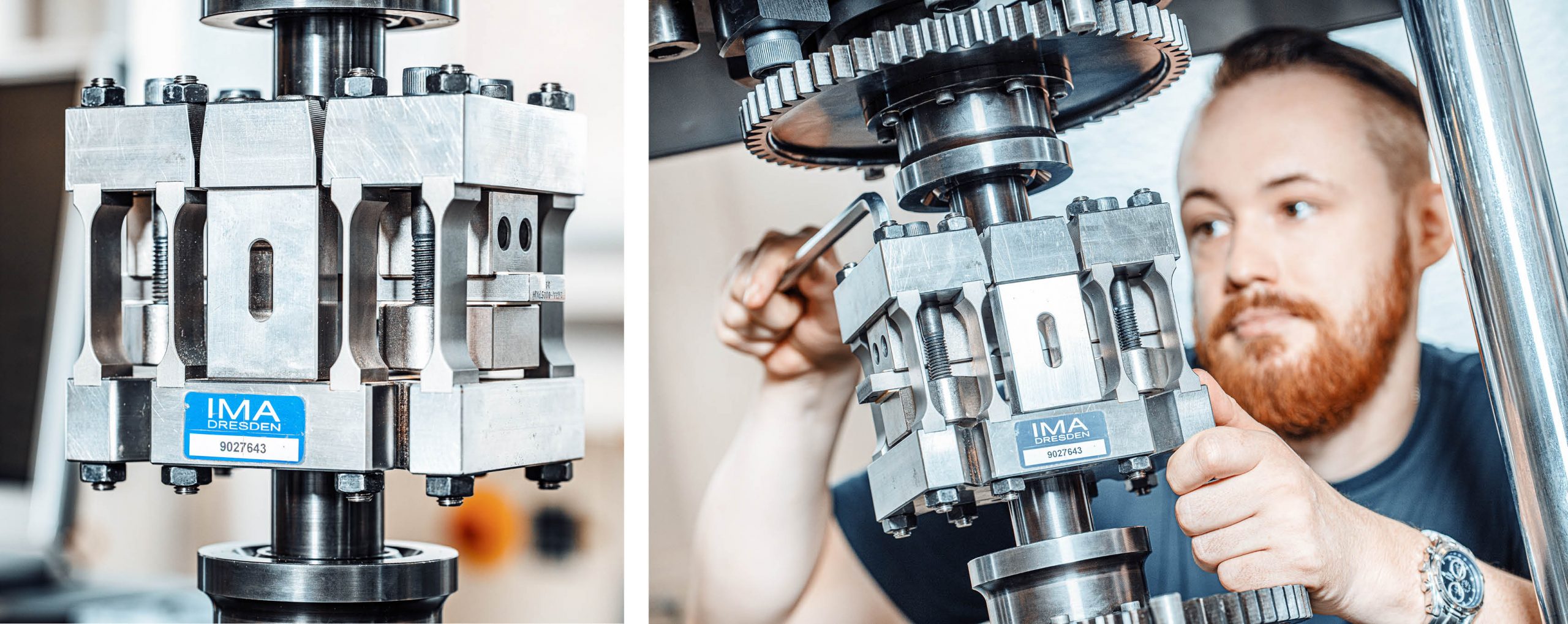

Bolts and bolted Joint Testing

In order to meet the requirements for stress and function-oriented bolted joints for a wide range of

components made of different materials, it is necessary to take a holistic view of bolting as a unit of

construction, joining process and materials.

- Quasi-static testing up to 2MN

- Fatigue testing

- Shear resistance testing

- Test bench in accordance with DIN 65151 for the determination of the loosening rotation

behavior according to DIN 25201-4, Appendix B (Junker test)- Nominal sizes M16 to M39 (different sizes upon request)

- Clamping length ratios KLV 1.7; 2.2 and 3.0

- Torque/ pre-tensioning force test according to DIN EN ISO 16047

Standards

Here you can see the standards of the tests of bolts and bolted joints.

- Bolted Joints:

– Locking behavior

– Torque / preload force

corrosion testing

Environmental influences and chemical loads during the production and application of your materials and

components can affect the quality of the products.

In our test laboratory, we determine the loading capacity of the test objects under real and extreme conditions

in accordance with generally accepted standards or to your individual test specifications.

- Steel (intergranular corrosion: e.g. Huey test or Strauss test)

- Aluminium materials (intergranular corrosion, e.g. ASSET test)

- Aluminium materials (exfoliation e.g. NAMLT test)

- Metals (stress corrosion cracking)

- Metals for aviation (intergranular corrosion, pitting corrosion)

- Mechanical-technological tests with media

Standards

Overview of standards for the field of corrosion testing.

Specimen Manufacturing

Our machining center enables us to produce samples according to conforming standards and your

requirements. From the raw materials, semi-finished products and components, we are able to

manufacture high-quality test specimens according to national and international regulations and/or

according to your specifications, irrespective of whether this relates to high-strength metallic materials,

ceramics, plastics or composite materials.

Spectrum

- Wet and abrasive cutting methods

- Water jet cutting

- Automated grinding, turning, milling and drilling machinery

- EDM (electrical discharge machining)

- Blast cleaning

- 3D Coordinated measuring

- Application of strain gauges and crack measuring foils

Non-standardised Tests, and Special Tests

We are well known for being able to master every technical testing challenge. Our experts from special

material test unit possess a high level of expertise for non-standard materials and component testing.

You describe the intended function of the parts – we develop the testing concept, organize the necessary

test and measurement technology, take care of the calibration of the sensors, implement the testing and

provide you with the final test report. Flexible accreditation from DAkkS (German Accreditation Body)

enables us to test materials and components according to different standards, as well as developing

new testing procedures

You are always welcome to send us requests regarding specific tests which you have not found in our

test portfolio. We will investigate whether we can support you in the requested test.

Standards

Here you can access the standards of non-standard and special tests.