Material Testing for Plastics and

Composite Materials

Lightweight construction and material testing are the insignia of the IMA Dresden – and our company

has been involved with plastics and composite materials since 1961.

Beneficial material properties, versatile areas of use and flexible dimensions gave the plastic and composite market a renewed boost. Today, wind energy, automotive and aerospace industries, along with the rail vehicle industry, are the continuous driving forces for advancing innovation with their demands.

IMA Dresden is an international testing and development centre for inspecting materials and will accompany and support you from the basic material onto production technology and up to, and including, the approval of the finished product. This service comprises not only static, cyclic and dynamic tests but also static long-term tests. The standardised and compliant material samples will be manufactured in-house with wide range of various manufacturing technologies. Furthermore, IMA Dresden has comprehensive experience in the fields of adhesive technology, laminate calculation as well as approval for materials.

We work according to German and international standards and guidelines (DIN, ASTM, ISO, etc.), or in accordance with factory settings. All relevant test laboratories are accredited according to DIN EN ISO/IEC 17025 and moreover are accredited for the business fields of “Material Testing of Metallic Materials” and “Material Testing of non-metallic materials according to SAE Aerospace Standard AS7003 by NADCAP” (National Aerospace and Defence Contractors Accreditation Programme).

Read brochure Search for standards

All testing norms for material testing for plastics and composite materials

Our portfolio

Starting Point for Non-metallic Materials and Connections

We assume the comprehensive determination for mechanical, thermal and chemical characteristics for you as well as determining the loading capacity of plastics, fibre-reinforced plastics, adhesive connections and/or joints hybrid material combinations.

Depending on the requirement, these tests can be executed at low and high temperatures as well as under media influence. We have extensive standard testing technology resources and experience in the design, construction and operation of special test benches for material and component testing processes.

We have also specialized in the comprehensive test topic of thermoplastic composite pipes. The qualification of the “thermoplastic composite pipes” ensures performance, reliability and safety during their service life using the DNVGL-ST-F119 (DNVGL-RP-F119).

Please feel free to contact us when you require a special solution for your testing requirements.

Please accept functionality cookies to display content.

Physical Tests

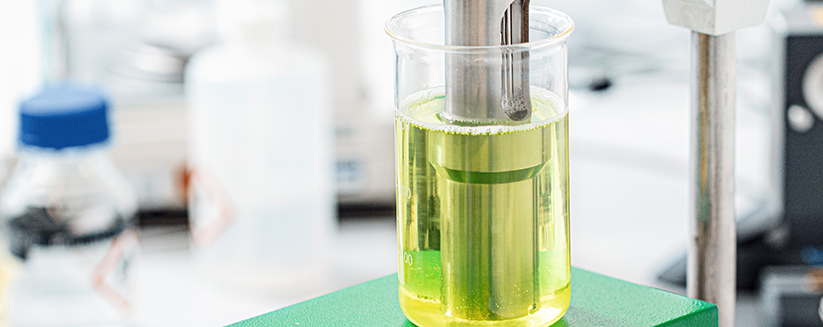

Our test laboratories enable us to not only determine and assess the specific physical characteristics but also the thermal properties of test materials. The wide-ranging scope of our audits has a high coverage: commencing with the fibre content provision to the determination of the glass transition temperature and up to conditioning of samples.

Standards

Here you can see the standards of the physical tests.

- Physical Testing – Mass determination

- Physical Testing

- Physical Testing – Conditioning

- Thermal analysis

- Sample measurement

Test spectrum

Physical tests

- Tightness

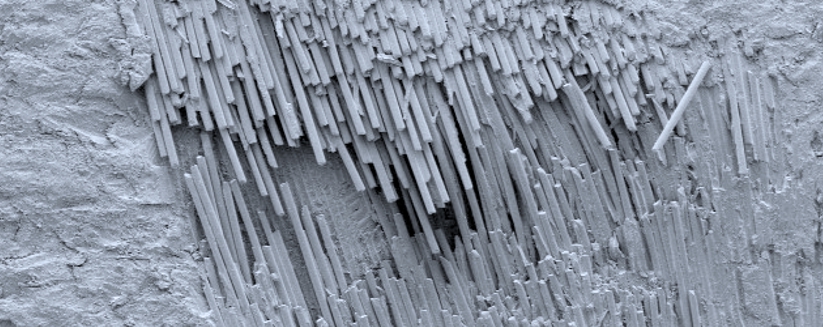

- Fibre content (GFK, CFK and Hybrid)

- Grinding analysis

- Fibre Distribution

Thermal analysis

- DSC (Dynamic

- Differential Thermal Analysis)

- DMA (Dynamic Mechanical Analysis)

- Dilatometry (determination of coefficient of thermal expansion)

Environmental audits

- Conditioning material and samples

- Water absorption

- Storage in aggressive fluids

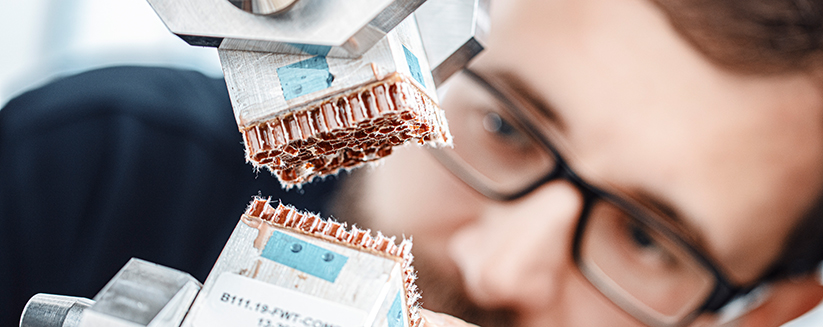

StatiC-Mechanical Material Test

We implement a wide variety of standard tests for the static characterisation of fibre composite materials. We will be pleased to advise you about which test standards apply for determining your material and the characteristic values. In principle, the tests can be accredited in accordance with all national and international standards, either with standard climatic conditions or under increased and lower temperatures. In addition, we can provide additional tests within the framework of flexible accreditation Category 2 in addition to standard procedures.

Standards

Standards overview in the field of static-mechanical testing.

- Compression testing

- Shear testing

- Tension testing

- Flexural testing

- Peel testing

- Determination of the energy release rate

- Impact testing

- Sample measurement

Test spectrum

- Tension, compression, bending, shear, connections

- Load range: 0.5 N – 4 MN

- Standard climatic conditions:

- 23 °C ± 2 °C, 50 % ± 5 % relative humidity

- Test under temperature influence:

- Temperature range: -55 °C up to 200 °C

- Screw connections

- Various devices for elongation measurement

- Specialised clamping / devices (IMA pressure testing device, IMA rail shear testing device)

Determining the energy release rate

- G1c Testing

- G2c Testing (3ENF, 4ENF)

- Mixed-Mode Testing

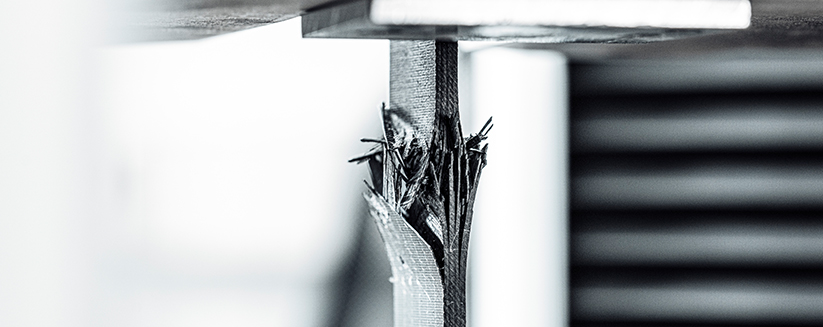

Impact testing

- CAI (Compression After Impact)

- Measuring the impact depth

- Impact on components

- Continuous stress impact on damaged

- components

- Determining the damage area

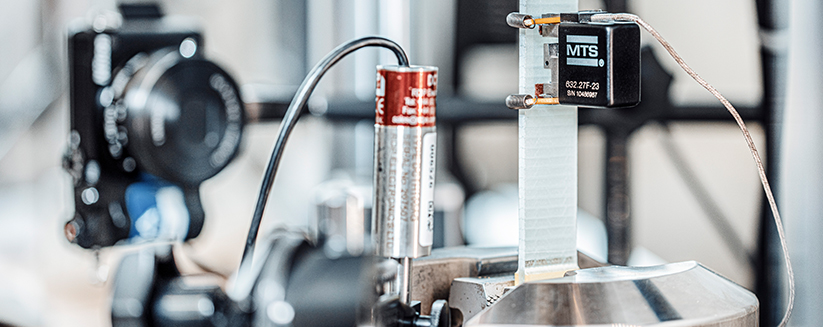

Material Fatigue tests

The cyclic testing methods require a high degree of expertise, as the versatile characteristics of this material group must be considered during the test. There is still a lack of recognised standards in this testing field. Our experts will be pleased to implement various tests for you.

Standards

See here the standards of the material fatigue tests.

Test spectrum

- Load range: 0.5 N – 2 MN

- Force, path or elongation controlled stresses

- Elongation and temperature measurements

- In-situ crack documentation (visual)

- Evaluation of Wöhler curves

- Fatigue testing under climatic influence:

- High temperature: +180 °C

- Climatic conditions: maximum 85 °C and 85% relative humidity

- Low temperature: -60 °C

Geometries and methods for fatigue tests

- Special double-sided waisted geometry for UD testing (IMA UDFA, IMA-up-UDFA)

- G1c, G2c Testing

- Buckling restraints for pressure load

- Geometries accepted by DNV GL

- Components and structures (e.g. rotor blade root element Connections)

Material creep tests

Components made of fibre-reinforced plastic should be designed to ensure long-term exposure. Material information regarding the behaviour of the component under long-term effects during static loading is therefore required. We implement these long-term tests under different loads as dependent on the temperature and media exposure.

Standards

Overview of standards for material creep tests.

Test spectrum

- Time-status creep testing

- Time-status breakage testing

- Type of load: Tension, pressure, thrust

- Load range: 0.1 N – 20 kN

- Extrapolation

- Creep testing under temperature and media influences:

- Time-status testing with media load (aggressive liquids)

- Combined creep loading (temperature and media)

- Time-status testing with exposure to high temperatures (-30 °C to 150 °C)

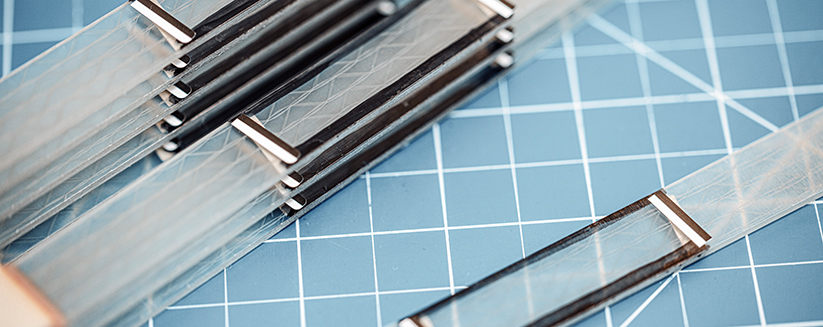

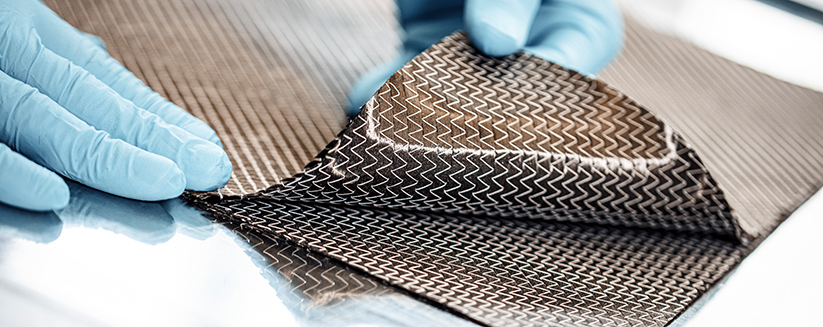

Preparing Laminates and specimen

Our laboratory can provide a wide range of various possibilities for the production of test laminates: from rovings, textile semi-finished products and resin systems. Benefit from our vast experience in the field of laminate production with vacuum infusion, RTM, thermoplastic processing and in the winding process. We will manufacture high-quality test bodies from the test laminates in accordance with national and international testing standards.

Manufacturing laminate:

- Vacuum infusion process

- Resin Transfer Moulding (RTM)

- Pre-impregnated processing

- Thermoplastic processing

- Winding process

- Thread impregnation

Manufacturing specimen:

- Sawing

- Drilling

- CNC milling

- Application of force transmission elements (cap strips)

- Water jet cutting

Standards

Here you can access the standards in the area of laminate and specimen production.

Monitoring and Certification for Construction Products

Fibre-reinforced plastics have been utilised successfully in the construction industry for many years. Special requirements hereby apply for this field of application with regard to the monitoring and certification of the materials.

IMA Dresden is an approved testing, monitoring and certification body (PÜZ) at the German Institute for Building Technology (DIBt) and can be also assume the monitoring and approval procedures within the framework of an approval in individual cases in addition to the necessary testing for the material.

This includes:

- Manufacturer monitoring (initial monitoring, control monitoring)

- Assembly monitoring

- Creating a certificate of compliance (CC)

Further information can be found on our site “Construction products“.

Standards

Standards overview in the field of monitoring and certification for construction products.

Component development

Are you looking for lightweight construction solutions with the highest efficiency? Take advantage of the almost limitless possibilities of fibre-reinforced plastics (FRP), such as e.g. high weight-specific strength, wide design freedom and freely adaptable material characteristics.

We can provide individual, tailor-made advice for implementing your ideas.

- Problem analysis

- Feasibility studies

- Material and technology consulting

- Project management

Concept Development

An idea develops into the concept. Commencing with basis of the specific requirements for a respective application case, we then develop fibre composite applicable solution proposals which are adapted to your demands.

- Compilation of technical specifications

- Developing design solutions

- Considering finished approaches

- Concept evaluation

- Optimising existing structures

Designing

The various, different concepts then result in detailed designs. We work with the following CAD systems during the designing process: Catia V5, Autodesk Inventor and AutoCAD.

Simulation

Which stresses are the components subjected to? During the calculation and simulation of FRP structures, with their complex material characteristics, we rely on the utilisation of state-of-the-art simulation software, such as Ansys, Patran/Nastran, Abaqus and SimulationX.

We can draw on our many years of experience and our extensive knowledge in dealing with FRP materials for the detailed assessment of the simulation results.

Manufacturing prototypes

Our technical centre can implement the manufacturing process for prototypes and small serial production products according to your wishes.

- Manual lamination process

- Vacuum infusion procedure (RIM, VARIM, VAP)

- Injection procedure (RTM, VARTM)

- Pre-impregnation procedure

- Press procedure

- 5-Axis winding machine

In addition, we also work closely with various industry partners from FRP processing together to enable a seamless transition to serial production

Test

In order to inspect the the fail-safe functionality of the developed components under real time conditions, we create and implement customised component tests under operating conditions. Our range of services hereby includes, among others, the following:

- Material characterisation

- Static, cyclic and dynamic component trials

- Climatic and temperature tests

- Testing under the media influences

In addition, we also accompany and support you with our extensive testing experience during the approval and certification of your products.

Quality assurance

We can provide a wide range of test procedures for the detection of possible production errors and faults or for detailed investigation of the damage behaviour for FRP components.

- Ultrasound testing

- Eddy current test

- Magnaflux test

- Endoscopy

- Modal analysis

- Optical measuring systems (Aramis, pontos)

- Monitoring/consulting for quality assurance