Environmental Simulation and

Vibration testing – We can create the

environment in the laboratory for you

Our engineers can provide you with extensive experience in the field of environmental simulation, where real

measured external influences such as vibration, shock, cold, heat, moisture, or splashing water can be mapped

on vibrating tables and in climatic chambers.

There is a vast field of work for you between development, quality assurance and the approval certification in all industries, including vibration testing, shock testing, climatic testing, Wöhler curve evaluation, pressure impulse testing, burst pressure testing, leakage testing, corrosion testing and transport simulation. A probit test, stair step process and a test for fuel resistance complement the portfolio.

We evaluate via experimental paths in order to verify the reliability of your product dynamic characteristics such as resonances, spring coefficients, damping variables as well as mass distributions. We will be pleased to monitor your technical equipment permanently on request (including data evaluation such as frequency analysis and estimation of the operating strength).

As an accredited test service provider, we not only provide standard-compliant component examinations but also, as an additional benefit, the flexible accreditation provides us with the opportunity to modify and to develop new test procedures.

Our portfolio

Multiaxial vibration test with/without thermal loading

Please accept functionality cookies to display content.

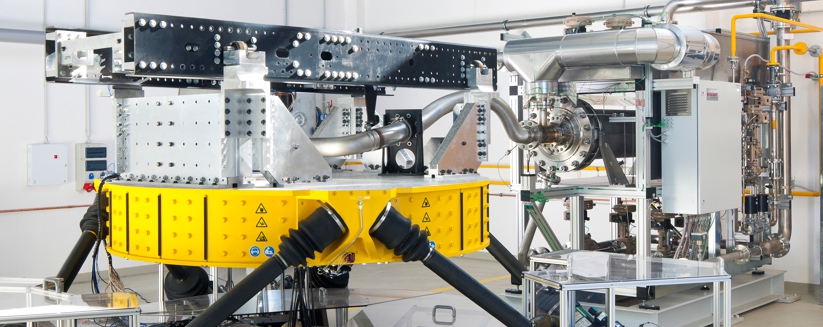

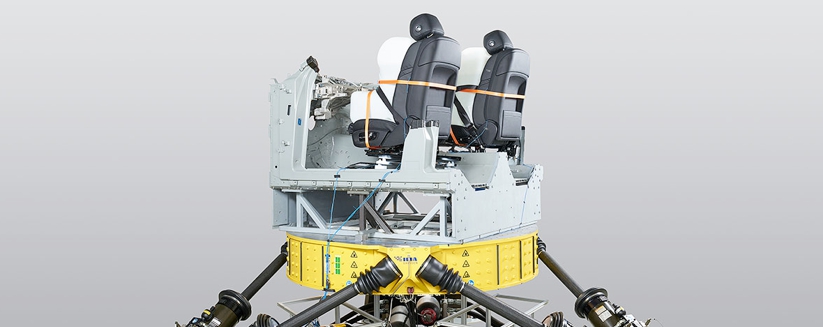

For operating load simulation for transport stress, we utilise a shaker test bench within the framework of the operating strength examination for the automotive industry, whose main components are a multi-axle oscillation table (MAST) and a combinable hot gas generator.

This test equipment is particularly suitable for testing components, modules, assemblies and subsystems such as, for example, tanks, attachment and dismantling parts, exhaust systems, roof and rear-mounted carrier systems, front-end modules, cooling systems and much more.

Utilising the multi-axial oscillation table (MAST) makes it possible to generate the loads from mechanical oscillations as regulated, whether for the simulation of the operating loads such as unevenness on roads, steering and braking loads, load interchanging and vertical and roll motions.

Exhaust systems and exhaust gas-carrying components are, for example, subjected to complex load conditions due to their function and location within the vehicle. On the one hand there are strong thermal-mechanical stresses due to the temperature of the exhaust gas. Meanwhile, these components have to withstand mechanical vibration loads arising from the motion of the vehicle and motor vibration impulses. The hot gas generator is capable of generating variable thermal-mechanical loads for components. Combining both systems allows the overlaying of stresses through experimental simulation. Both systems can be operated independently of each other.

Parameter

- Table size: Diameter 2.2m

- Payload: maximum 680kg

- Acceleration: maximum 200m/s²

- Frequency range: 0.5..100 Hz

- Burner power: maximum 700 kW

- Test bench operation: 24/7 is possible

- Hot gas mass flow: up to 0.850 kg/s

- Hot gas temperature: up to 850°C

- Interfaces:

- 16 accelerations (can be extended as preferred)

- 24 additional analogue inputs

- 8 analogue outputs

- 16 digital inputs and outputs

Vibration testing

We can test your products, components and assemblies in our modern vibration laboratories as standard compliant for their behaviour and reliability in the event of vibration and shock loads. Our laboratories are equipped with electro-dynamic shakers for 9 KN up to 60 kN forces with sliding table as well as a transportable climatic chamber for simultaneous temperature and humidity loads for the test specimens.

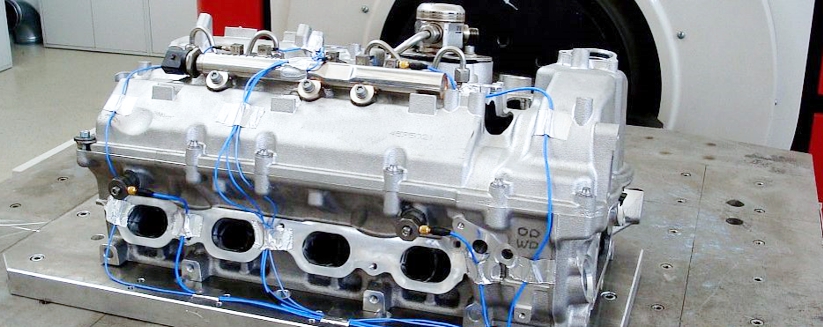

Would you like to have vibration and shock tests under climatic influences? We simulate loading conditions in a wide temperature and humidity range. Development-supporting product validations include additional testing methods such as pressure impulse testing, burst pressure tests, leakage tests e.g. in the case of fuel rails.

Test spectrum

- Vibration testing

- Vibration examinations

- Oscillation tests

- Combination tests with oscillation, vibration, shock and climate

- Pressure impulse tests, burst pressure tests

- Tightness test

- Corrosion testing

- Transport simulation

- Probit test

- Wöhler curve evaluation

- Stair step procedure

- Sonic fatigue test

- Testing for fuel resistance

Test parameters

Vibration test

- Swept sine, noise, higher-level excitation, idling resonance

- Frequency range 1 up to 3500 Hz

- Force vector 60 kN

- Test acceleration up to 140g

Shock test

- Half-sine, saw-tooth, trapezoidal, Shock Response Spectrum (SRS) among others

- Peak acceleration up to 200 g

- Shock duration 1-50 ms

Specimen mass

- Horizontally excited up to 2000kg

- Vertically excited up to 1000 kg

- Oscillation and shock also combined with temperature and humidity load

Climatic test

- Usable space 1 m³

- Temperature range -70 up to +180 °C

- Relative humidity 10-98%

- Temperature shock -80 °C … +220 °C

Test standards

Selection of national and international standards, testing requirements from certification bodies and manufacturer’s provisions or regulations

| DIN EN 60068-2-6 | FC Tests: Vibration sinusoidal |

| DIN EN 60068-2-27 | Ea Tests: Shocks |

| DIN EN 60068-2-50 | Z/AFc Tests: Combined Testing – Cold/Vibration |

| DIN EN 60068-2-51 | Z/BFc Tests: Combined Testing – Dry Hot/Vibration |

| DIN EN 60068-2-64 | Fh Tests: Broadband Noise |

| DIN EN 60068-2-80 | Fi Tests: Mixed-Mode Vibration Testing |

| DIN EN 60068-2-81 | Ei Tests: Shocks – Synthesis for Shock Response Spectrum (SRS) |

| MIL-STD-810 | Test Method Standard for Environmental Engineering Considerations and Laboratory Tests |

| RTCA/DO-160 | Environmental Conditions and Test Procedures for Airborne Equipment |

| DIN EN 60 721 | Classification of Environmental Conditions |

| DIN EN 50 125 | Environmental conditions for operating resources and equipment on railway vehicles |

| DIN EN 50 155 | Electronic equipment used on rail vehicles |

| DIN EN 61 373 | Operating resources for railway vehicles |

| ETSI EN 300 019 | Telecommunication |

| VW 801 01 | Electrical and electronic assemblies in motor vehicles |

| BMW GS 95003 | Electric/electronic assemblies in motor vehicles |

| ISO 16750-3 | Road Vehicles – Mechanical Loads |

Pressure Pulse test

We can execute pressure pulse testing, leak tests, burst pressure tests on hydraulic components, pipework, fittings, fixtures, fuel lines, injection systems and rails. This enables the pressure pulse strength to be tested with indoor dynamic tests. Combining pressure pulse tests and vibration tests in accordance with IACS and DNVGL Type Approval also enables hydraulic fittings to be tested for bending with loads for internal pressure.

Certification tests for hydraulic systems are just one part of our testing spectrum as well as comprehensive validation inspections e.g. for fuel rails.

Test spectrum

- Pressure impulse testing

- Hydro pulse tests

- Combined pressure pulse testing and vibration testing (IACS, DNVGL)

- Bursting pressure test

- Leakage tests with various media (oil, water, nitrogen, helium among others)

- Pull-Out-Test

- Vacuum testing

Test parameter

| Pressure, dynamic | Dynamic maximum pressure up to 1,400 bar Typical pulse frequency 1 Hz Up to 30 Hz sinusoidal |

| Vibration | Bending frequency of hydraulic pipes or tubes up to 20Hz |

| Curve shapes | Sine, triangle, trapezoidal or standard curves e.g. according to IACS P2.11.5.5.3, DNVGL among other things |

| Temperature | Ambient temperature -40°C up to 140°C |

| Pressure,static | Burst pressure testing up to 4,000 bar |

Test Standards (Selection)

| IACS Req. 2011 | International Association of Classification Societies | Requirements concerning pipes and pressure vessels P2.11 Type Approval of Mechanical Joints |

| GL | Germanischer Lloyd | Classification Provisions and Construction Provisions for Pipework Fittings |

| DNV | Det Norske Veritas | Standards for Certification No. 2.9 Type Approval Program No. 5-792.20 Pipe Couplings |

| DNVGL | DNV GL SE | CLASS PROGRAMME Type approval Mechanical joints DNVGL-CP-0185 |

| BS 4368 Part 4 | British Standard | Compression couplings for tubes |

| ISO 19879 | International Organisation for Standardisation | Test procedure for metallic pipe fittings utilising fluid technology |

| ISO 6605 | International Organisation for Standardisation | Hydraulic fluid power. Hoses and hose assemblies. Test methods |