Optical Measuring Methods

Non-contact measuring and non-destructive testing by utilising optical measuring methods.

State-of-the-art measurement techniques such as Digital Image Correlatin (DIC), trigonometry, focus variation or confocal microscopy, laser interferometry or white-light interferometry (WLI), high-speed digital video or also thermography enable what is hidden from the human eye to be made visible and numerically measureable. The results, which can be obtained with optical measuring technology, contribute to a significant gain in knowledge for a multitude of different examinations.

The capabilities available with the optical-based and/or camera-based measuring and analysis methods create a wide range of possible applications:

- Traceable calibrated measurement of 2D and 3D objects

- Standard-compliant determination of surface roughness (also on 3D curved surfaces)

- Monitoring the most varied structures by utilising visualisation for deformations, displacements and strains while subjected to static and dynamic load cases

- Measuring temperature distributions and detection of local load peaks by utilising thermography

- Long-term recording of high-frequency vibration modes

Our portfolio

All the technologies, which are available, can be applied as standard-compliant individual inspections or tests or supportive and/or supplementary analysis methods during performing a wide variety of inspection or test scenarios. These systems can be selected for utilisation either in the laboratories of IMA Dresden, as partial systems or also mobile at your preferred location.

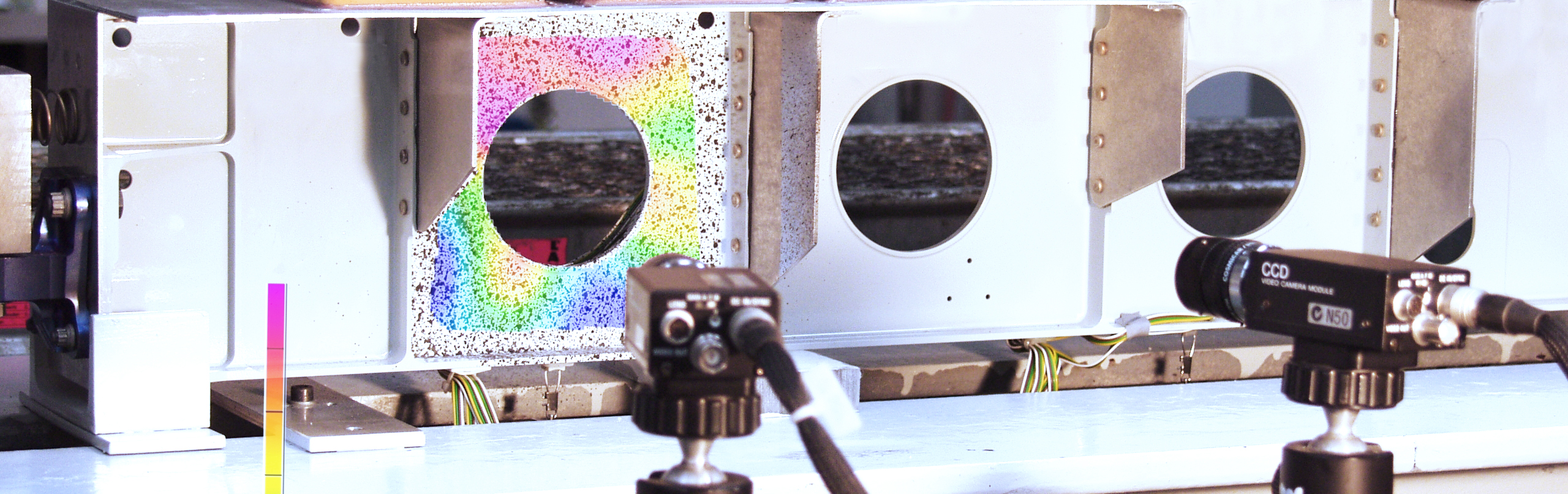

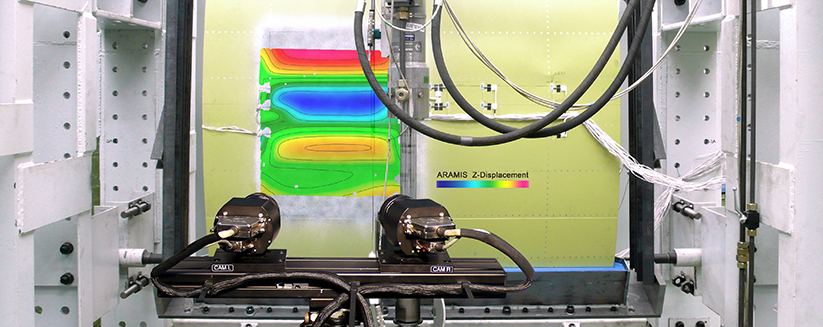

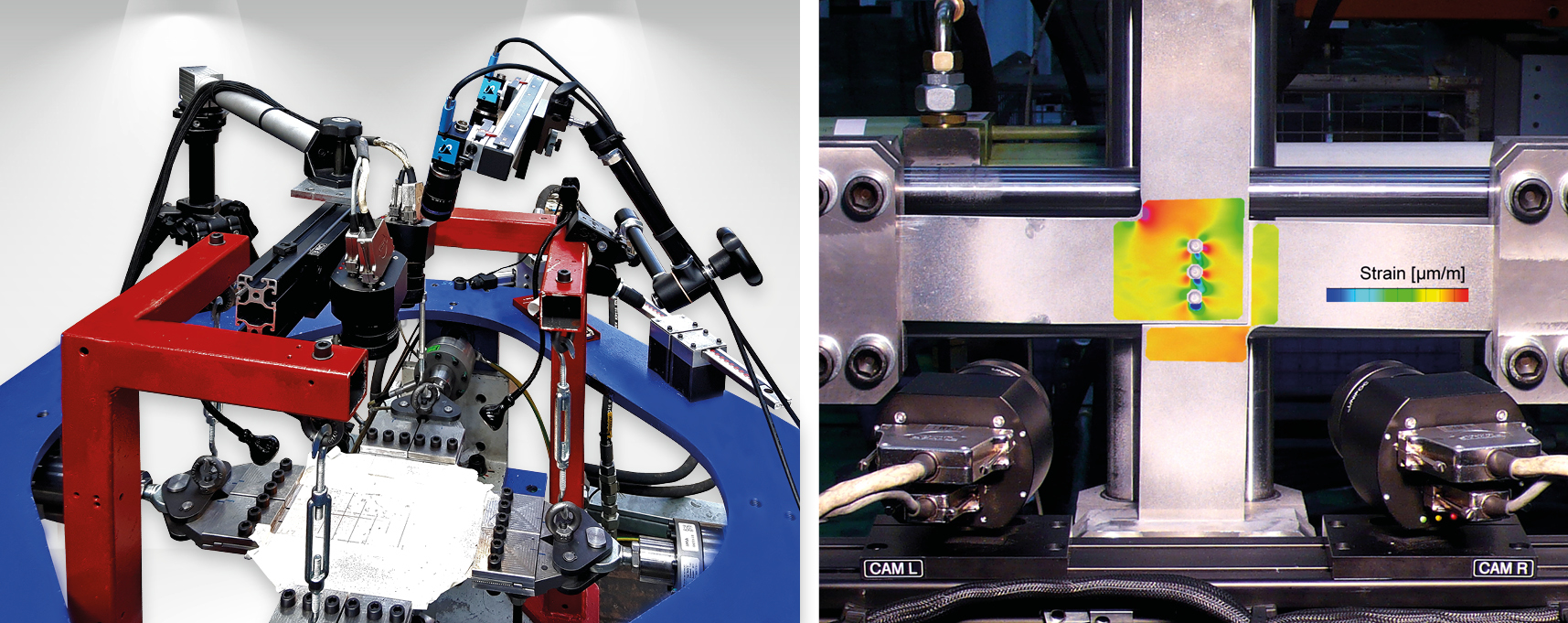

Our engineers will always be pleased to develop an inspection or test concept which is specifically customised to your requirements which will, of course, always incorporate our many years of know-how with optical measuring methods. Just one example for this is that, more than 20 years ago, IMA Dresden was the first German industrial company to utilise the DIC ARAMIS system relating to optical in-situ strain measurement on aircraft structures in a test environment.

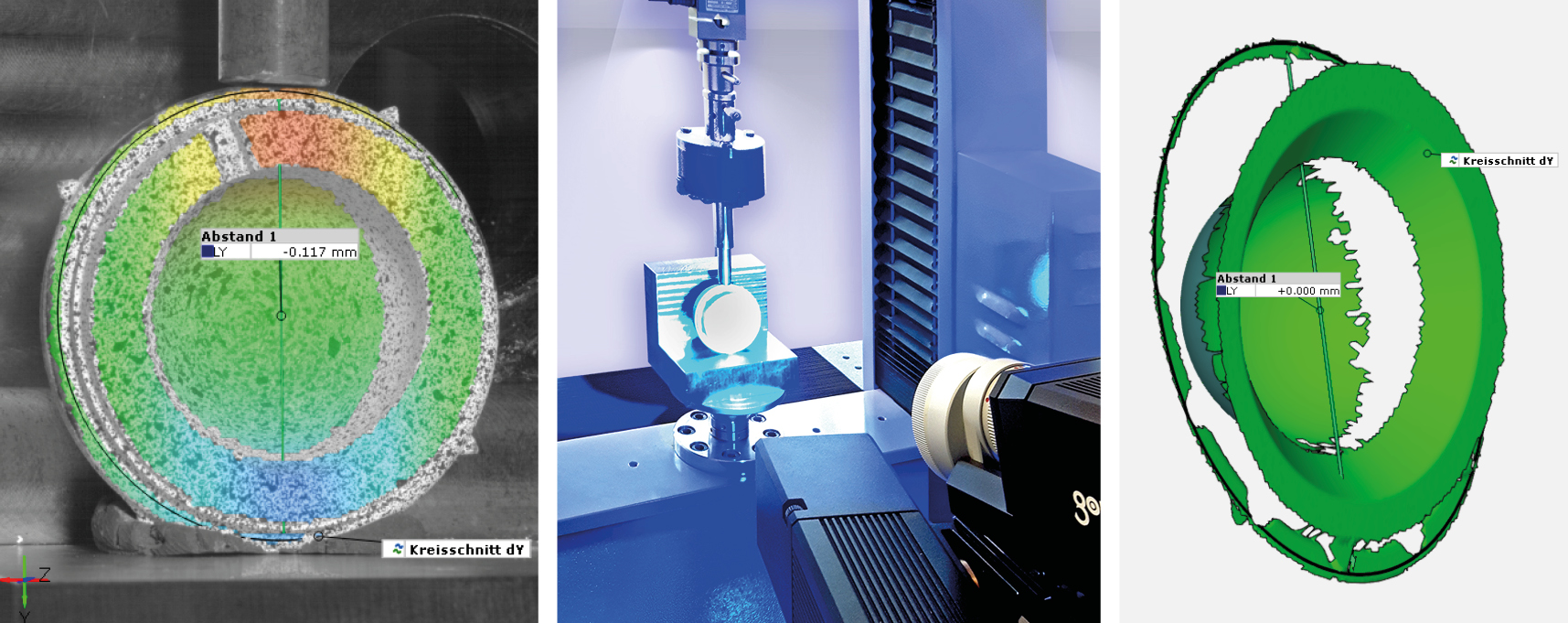

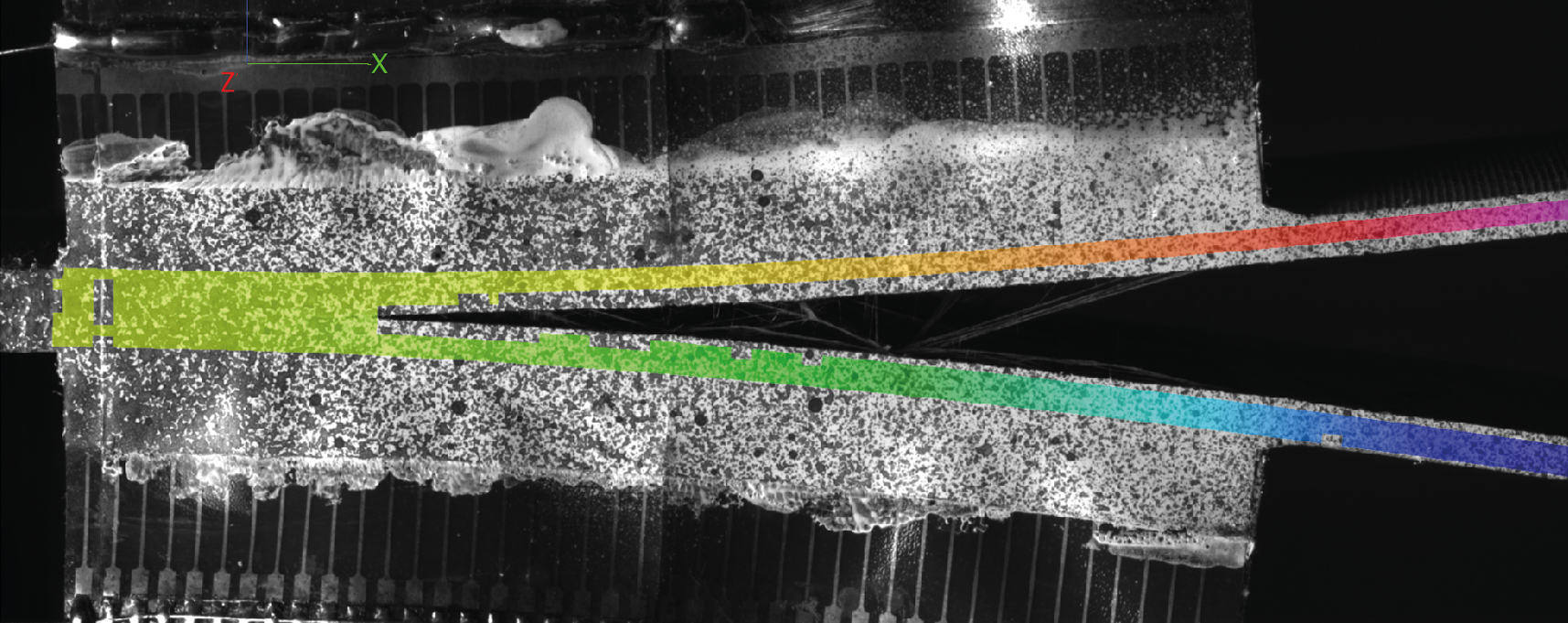

Vectors of displacement measures at marker dots by ARAMIS at a segment of an airplane (flight simulation) Measure of geometry, displacement and strain by ARAMIS for validation of a hip cup implant Experiment for optical crack-tip tracking by usage of displacement measures by ARAMIS Test of biaxial loading for strain measures and crack analysis by ARAMIS

Application possibilities for optical [measurement] / [test] methods [at IMA Dresden]

- Non-destructive and non-contact measuring

- Measuring geometric dimensional accuracy on 2D and 3D objects

- Geometrically referenced measuring – planar and stereoscopic up to 360° circumferentially

- Area, surfaces, volume and local resolution selectable according to requirements

- Test frequencies of up to 2 kHz for long-term measurements (life time, fatigue, creep)

- Displacements and deformations with 6DoF, elongations

- Vibration shape analysis and frequency analysis for rotating and oscillating test parts

- Standard-compliant determination of digital 3D shapes, contours, dimensions, roughness specifications

- Comparison with and/or transfer of data records generated from/to CAD and FEM to enable reverse engineering utilising standardised data interfaces

Technologies

- 3D optical measuring and digital image correlation with ARAMIS 12M

- Trigonometry and measurement point acquisition with TRITOP, theodolite or laser tracker

- Measurements and documentation by utilising digital video and high-speed cameras up to 10 kHz

- Large scale 3D surveys and reverse engineering by means of laser tracker scanning

- Microscopic 3D surface finish analysis and roughness determination according to standard

Areas of application

- Materials: Plastic materials and composite materials, metals

- Materialography, material coefficients

- Strains, elongations, fields, inhomogeneities

- Fatigue, failure, crack propagation

- Vibrations, natural frequencies

Application fields according to industries

- Aerospace: Fuselage elements, shell, tail units, landing gear, interior, assemblies

- Railway: Carriage bodywork, bogies, wheelsets, traction units, interior, assemblies, rail systems

- Automotive: Vehicle structures, chassis, powertrain, assemblies

- Transport / Construction machinery: Load-bearing structures, undercarriages, transmissions, lever systems, large components, drive units, power transmission, assemblies

- Medical products: Implants, prostheses, movement processes, OP tools, orthopaedic auxiliary aids