Non-destructive testing

Non-destructive testing methods are used to investigate damage progression in component testing, and also help to investigate instances of damage, serve as a form of quality control, and are used for product monitoring purposes. In addition, they are widely used in the maintenance and repair of vehicles, components and systems.

In such cases, our qualified inspectors offer extensive experience in planning, coordinating and implementing large-scale testing and inspection activities, from coupon testing to across-the-board permanent monitoring of technical equipment.

In our own laboratories, but also at your premises, we can make statements regarding the quality of your test item. Our test personnel are qualified according to the ISO 9712 and EN 4179 standards and offer many procedures that allow non-destructive testing. We work according to German and international standards and guidelines (DIN, ASTM, ISO, etc.), or in accordance with factory settings.

Aviation-specific NDT courses on eddy currents and ultrasonic testing also take place at IMA Dresden. These are in line with DIN EN 4179 and NAS 410. Our non-destructive testing training is accredited by NANDTB-Germany and meets the EASA AMC 145.A.30(f) requirements.

Our portfolio

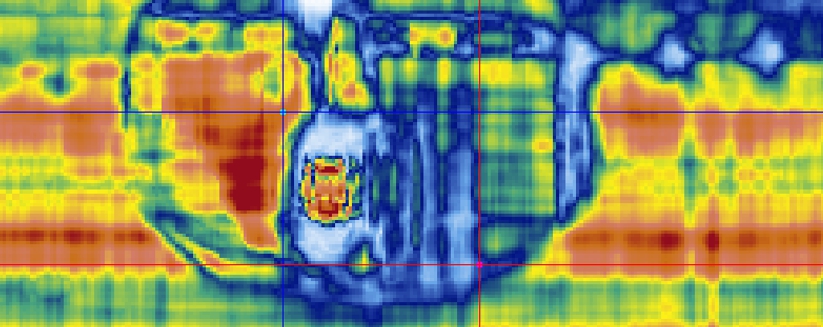

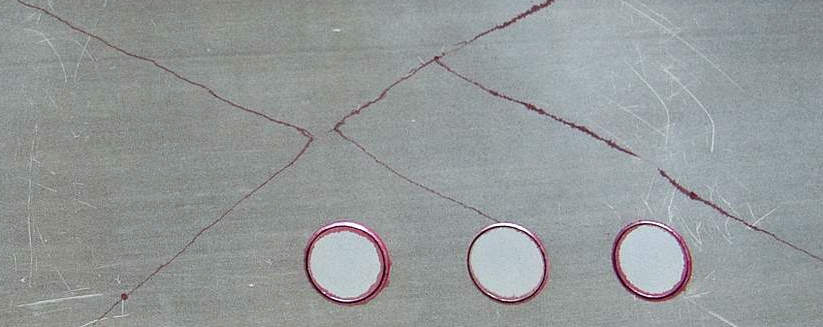

The interdisciplinary area of Non-Destructive Testing at IMA Dresden examines structures and components in the test phase and in real use in cases of damage. Moreover, it examines when and where damage occurs, how it develops and how a structure reacts to cyclic loads after an impact. Delaminations, material deviations, tears or foreign material that has entered are made visible, allowing conclusions to be drawn about materials, technology, processes, operation and optimisation.

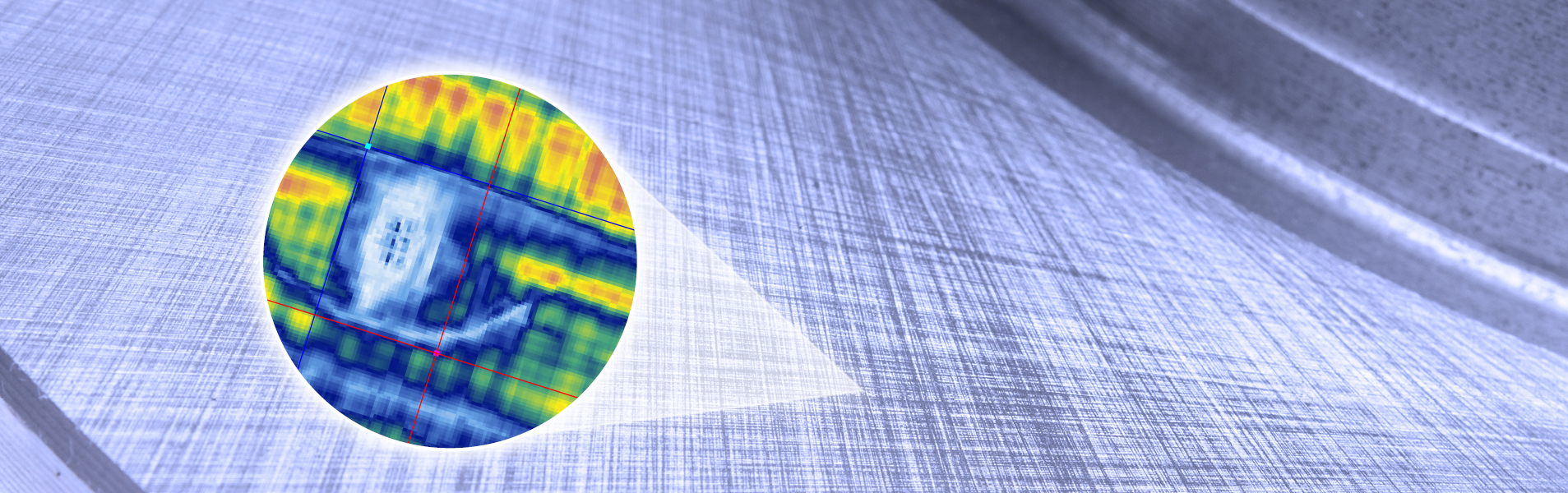

For this we use the very latest testing techniques and tailor-made testing concepts. Alongside the traditional methods that make use of manual testing, we also use special procedures such as the immersion technique, the phased array technique on CFK, GFK und GLARE® and the four-frequency rototest. Our specialists in non-destructive testing will help you with the most suitable procedure for your Needs.

With our extensive experience in non-destructive analysis of metallic materials and fibre composite materials, as well as myriad component analysis, from bogies to the Airbus A380-800, our non-destructive testing specialists will provide you with assistance and offer you the full range of non-destructive testing services, from a feasibility study through to the development of testing procedures, implementation, evaluation, recording and the results report.

Testing methods

Ultra sonic test (UT)

- Mobile testing

- Contact technique

- Phased array technique

- Immersion technique

Eddy current test (ET)

- Mobile testing

- Multifrequency testing

- Conductivity measuring

- Measurement of layer thickness

- Surface crack testing

Magnaflux test (MT)

- Fluorescent magnetic particle inspection

- Black/White contrast magnetic particle inspection

Penetration test (PT)

- Fluorescent penetrant testing

- Dye penetration testing

Visual inspection

- Direct visual inspection

- Indirect visual inspection (endoscopy)

Thermography (TT)

Tap test

Optical test methods (ARAMIS, PONTOS)

Aviation-specific non-destructive testing training courses

IMA Dresden holds several courses every year on non-destructive testing procedures. In cooperation with EFW Elbe Flugzeugwerke GmbH, aviation content is taught at the training centre in Dresden, based on material from the NANDTB.

The training is focused on future-oriented topics: the requirements of a maintenance company and specific aspects of component testing, knowledge of materials and approval tests. Another plus is that new developments in aviation, such as manufacturing processes, materials and test methods, are continually being incorporated.

Find out more on our “Training” site.