Materialography

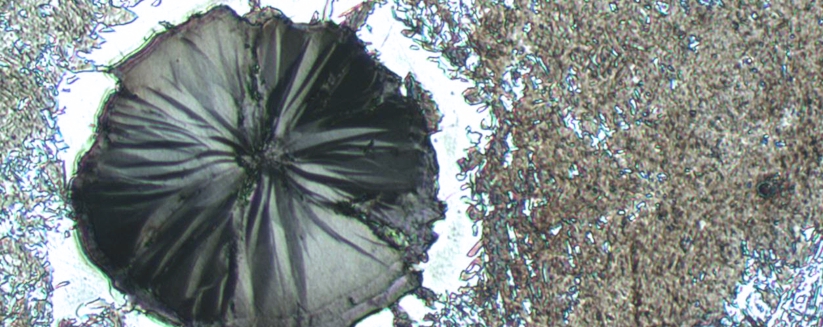

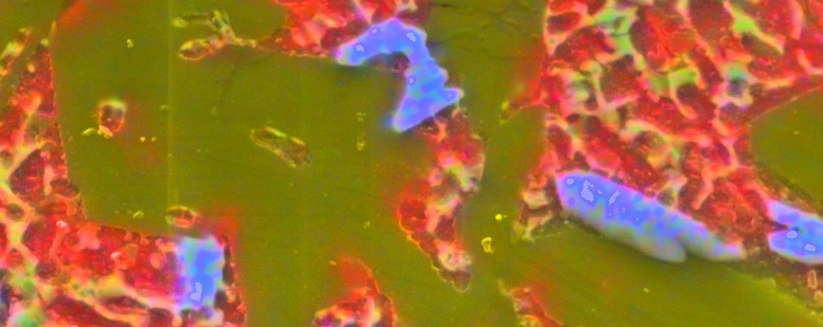

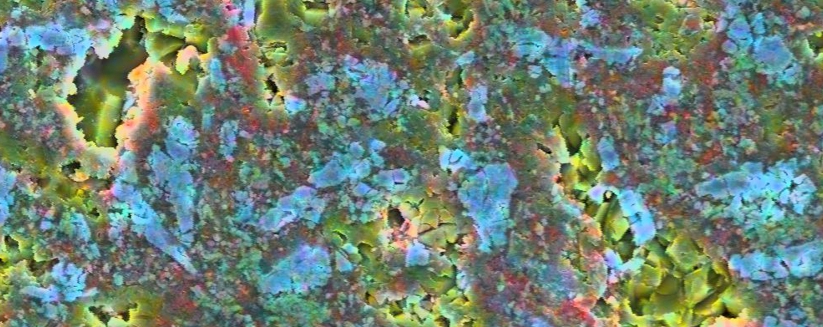

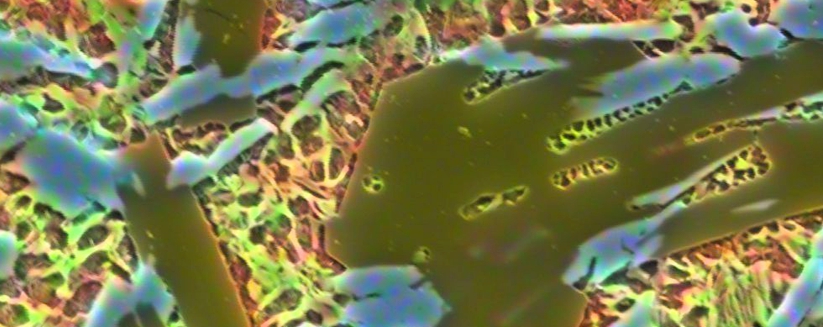

Countless new products are based on new materials and innovative manufacturing processes, whose success would not have been possible without materialography, i.e. the visual representation and evaluation of inner microstructures, the associated improvement of material properties, optimisation of processes and quality assurance in production.

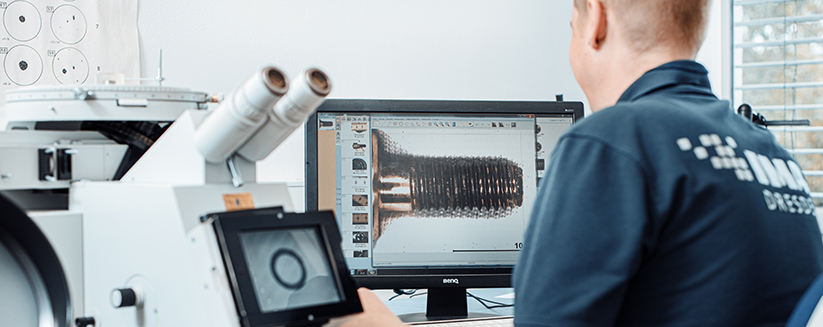

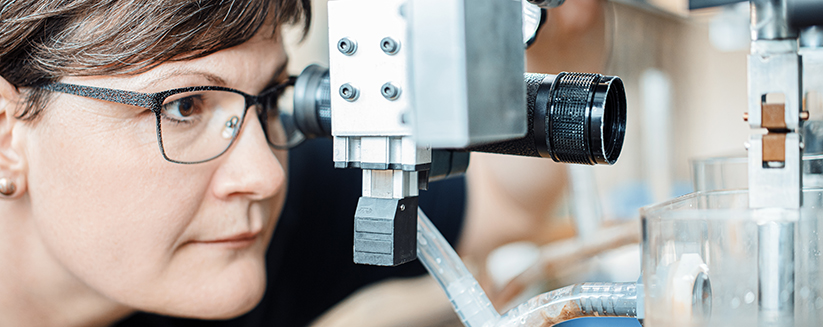

Whether the objective is quality assurance, damage analysis or research and development, in our accredited materialography laboratories we examine both metallic and non-metallic materials of different compositions using the appropriate qualitative and quantitative characterisation procedures.

This includes the test preparation process and the use of all microscopic methods from light to electron microscopy for the analysis, evaluation and documentation of microscopic research results. The investigations can be supported and supplemented by further materials analysis, technological and physical procedures on request.

Our portfolio

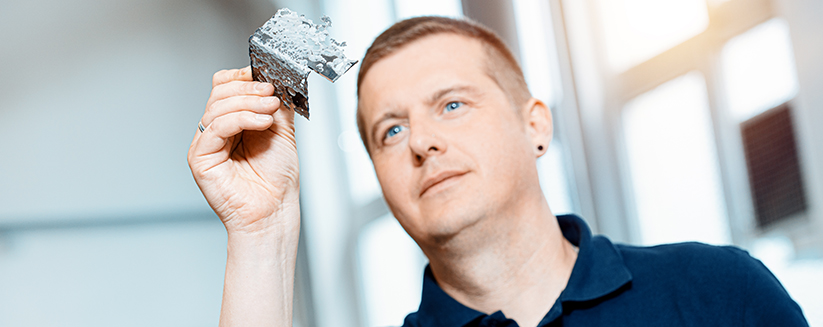

From mechanical engineering, the metal and plastics industry, energy and medical technology, insurance and surveying to rail vehicle technology and other transport sectors, our materialography laboratories offer all of the current investigation methods on different materials, from steels, cast iron, aluminium, copper and titanium alloys and powder metallurgic materials to plastics and composite materials for conventional and new manufacturing processes, such as additive manufacturing.

From sample preparation to microscopy and material analysis, we assess the material condition, surfaces, edge layers, joins and fractured surfaces for you. As part of our overall approach to the materials, we offer you the opportunity to asses the relationships between the technology parameters and the structural properties, for example when optimising your production technologies.

Please accept functionality cookies to display content.

Sample preparation

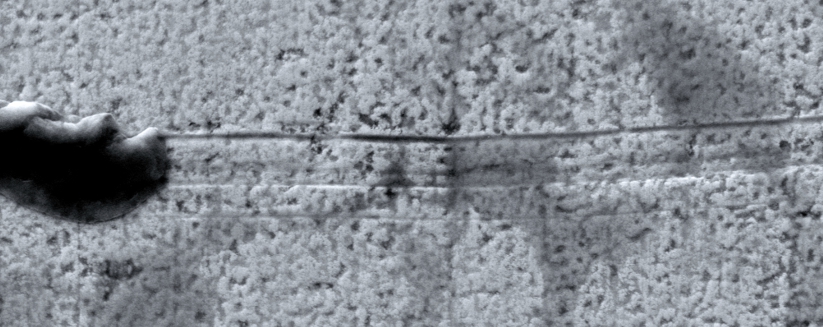

Careful preparation forms the basis for microstructure characterisation, This requires the utmost accuracy, manual dexterity and skill, garnered over many years of well-founded training and practice. Only then can the properties of the material be determined and evaluated properly.

Our mechanical manufacturing centre allows us to produce material samples using non-destructive sample separation and preparation techniques (e.g. separation, embedding, sanding and polishing) in line with requirements and specifications. This applies whether you are dealing with high-strength metallic materials, ceramics, plastics or composite materials.

- Wet and abrasive cutting methods

- Waterjet cutting

- Automated grinding, turning, milling and drilling processes

- Eroding

- Blast cleaning

- Cold- and light-curing embedding processes (high edge definition)

- Manual and automatic grinding and polishing processes

- Conventional and modern etching methods for microstructural contrasting

Materialography

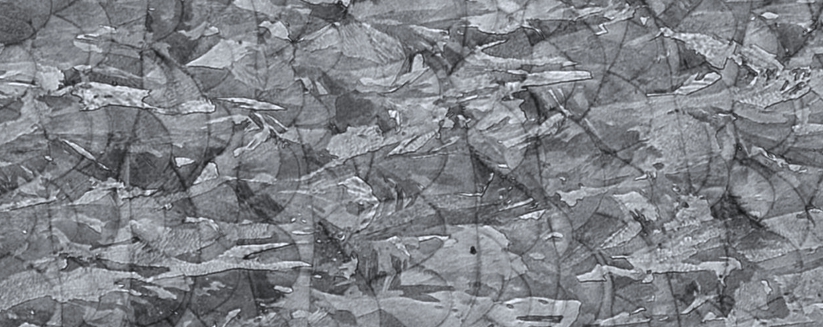

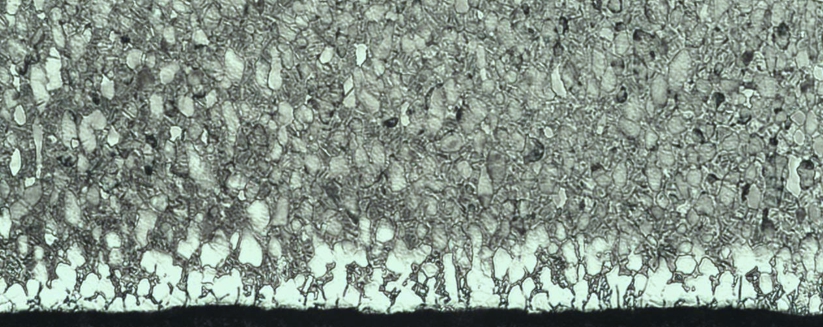

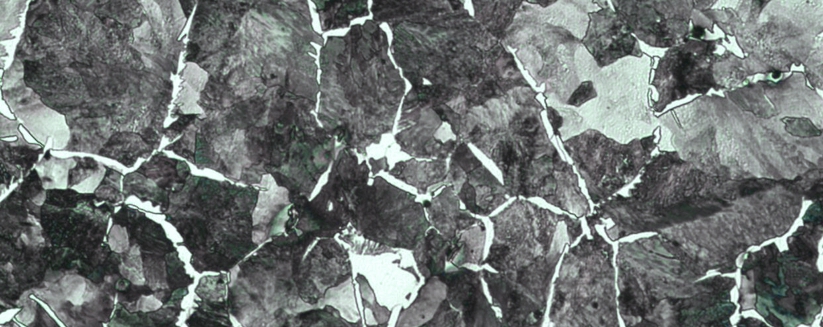

The following materialographical and supplementary testing methods are available in order to be able to carry out investigations into material quality, microstructure formation, surface and edge layer structure, weld seam quality or possibly damage characteristics. Based on this, we can answer your questions regarding development, quality assurance and damage assessment.

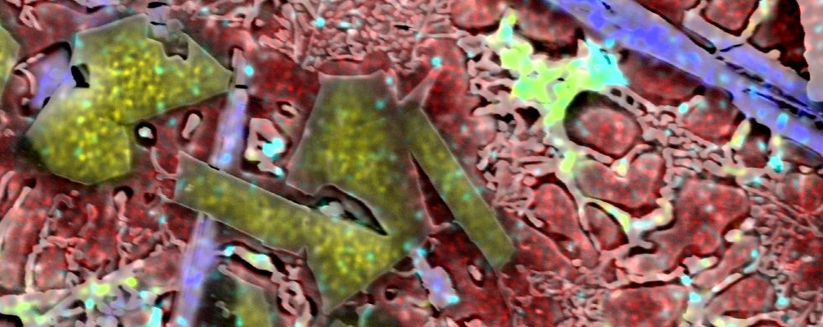

- Light and scanning electron microscopy incl. EDX analysis

- Evaluation of the microstructure

- Evaluation of the surface, separation cut, welded and soldered seam quality

- Determination of grain size

- Determination of purity level

- Measurement of layer thickness

- Changes in surface layer (carburisation, decarburisation, alpha case, corrosion, oxidation, alloy depletion)

- Determination of cell sizes (PUR)

- Evaluation of homogeneity and carbon black dispersion (PE)

- Roughness and profile measurements

- Hardness testing (macro/small load/Micro)

Standards

- General metallography

- Boundary layer change

- Metallography – boundary layer changes

– decarburization

– alpha-case

– corrosion

– layer thickness

- Metallography – boundary layer changes

- Degree of purity of steels

- Determination of grain size

- Hardness test

Chemical composition testing

Our materialography laboratories have various spectrometers for qualitative and quantitative elemental analysis. We can identify materials and components with regard to the type of material or check the element content requirements according to standard (e.g. DIN EN 1982, ÖNORM B 5024-3), according to metal assessment basis (e.g. assessment basis for metallic materials in contact with drinking water – UBA list) or according to specification.

With local analytics, it is possible to analyse individual metallographic constituents, corrosion products, operating residues or wear particles, for example.

- Optical emission spectroscopy (F-OES) for steels, aluminium and copper alloys (Co-, Ni-, Ti-materials and cast iron on request)

- EDX analysis (local element analysis) in connection with scanning electron microscopy

Standards

Here you can find the test standards in the field of chemical composition.

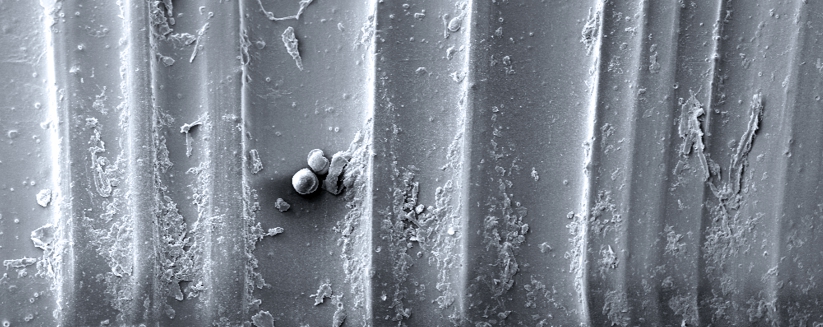

Tribological testing

The friction and wear behaviour of metals, ceramica, plastics and composite materials or coatings can have a considerable influence on the functionality of a part or of the entire component.

Our test laboratory determines the behaviour in use of the test objects for you, taking into account the technological parameters and attainable material properties, and advises you on how to optimise the technology, application and service life of your product. The focus is on recognising the effective wear mechanisms and replicating the tribological systems in model test arrangements. Here we vary load parameters such as force, speed, temperature, intermediate, lubricant and climate, and record the measuring figures with comprehensive electronic measuring technology. The evaluation may be supported by material analysis and physical procedures.

- Testing the abrasion resistance of various materials

- Determining the friction coefficient

- High-speed abrasion test

- Component oriented test rigs

- Evaluation using gravimetry, roughness and profile measurement

- Surface and microstructure assessment with microscopic processes

Standards

Overview of standards in the field of tribological testing.

Corrosion testing

Environmental and chemical influences during the production and use of your materials and components can adversely affect the quality of the products. In our test laboratory, we determine the loading capacity of the test objects under real and extreme conditions in accordance with generally accepted standards or to your individual specifications.

- Resistance testing against intergranular corrosion for steels (Huey test, Strauß test) and aluminium materials (ASSET test)

- Resistance testing against layer corrosion (exfoliation) for aluminium materials (NAMLT test)

- Resistance testing against intergranular corrosion and/or pitting corrosion for metals in the aviation industry

- Mechanical and technology testing under the influence of different media

- Evaluation using gravimetry, roughness and profile measurement

- Surface and microstructure assessment with microscopic processes

Standards

Overview of standards for the field of corrosion testing.