Electrical testing on parts, components and systems

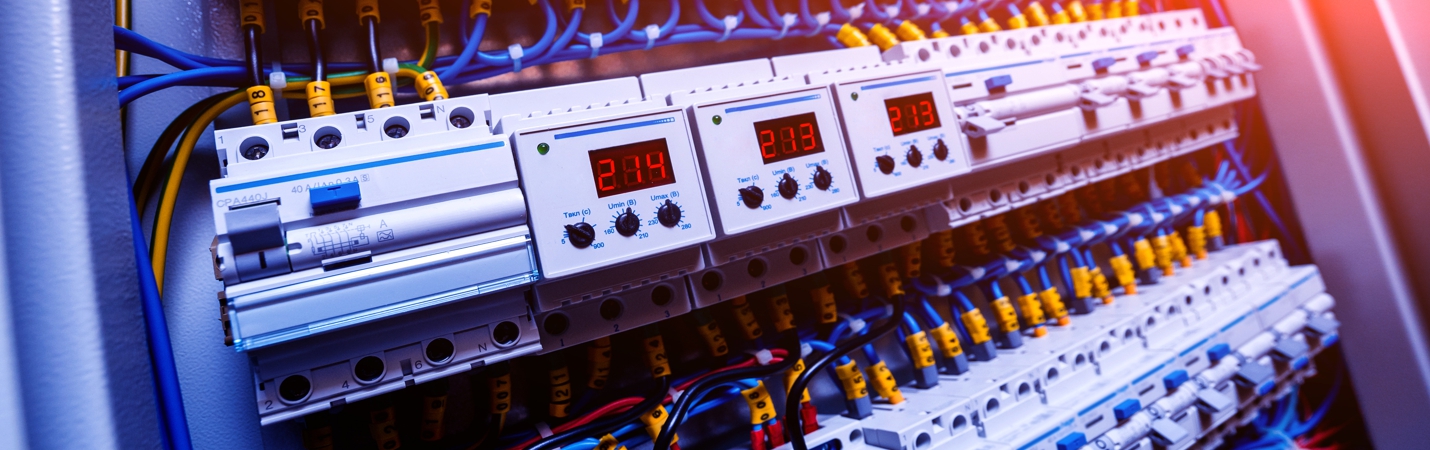

We test electronic, electrical and electromechanical parts, components and systems for functionality, quality,

safety and compliance with the various technical specifications.

With the help of a wide range of modern test methods and the extensive specialized knowledge of our

employees, we test connectors, switchgear and switchgear combinations across all industries;

from short-circuit tests to operating behavior and insulation tests.

Whether electrical engineering, automotive, rail vehicles or mechanical engineering – we work according to

German and international standards and guidelines or according to factory specifications.

All relevant test laboratories are accredited according to DIN EN ISO/IEC 17025.

Read brochure Performance Overview Electrial testing automotive Search for standards

Our portfolio

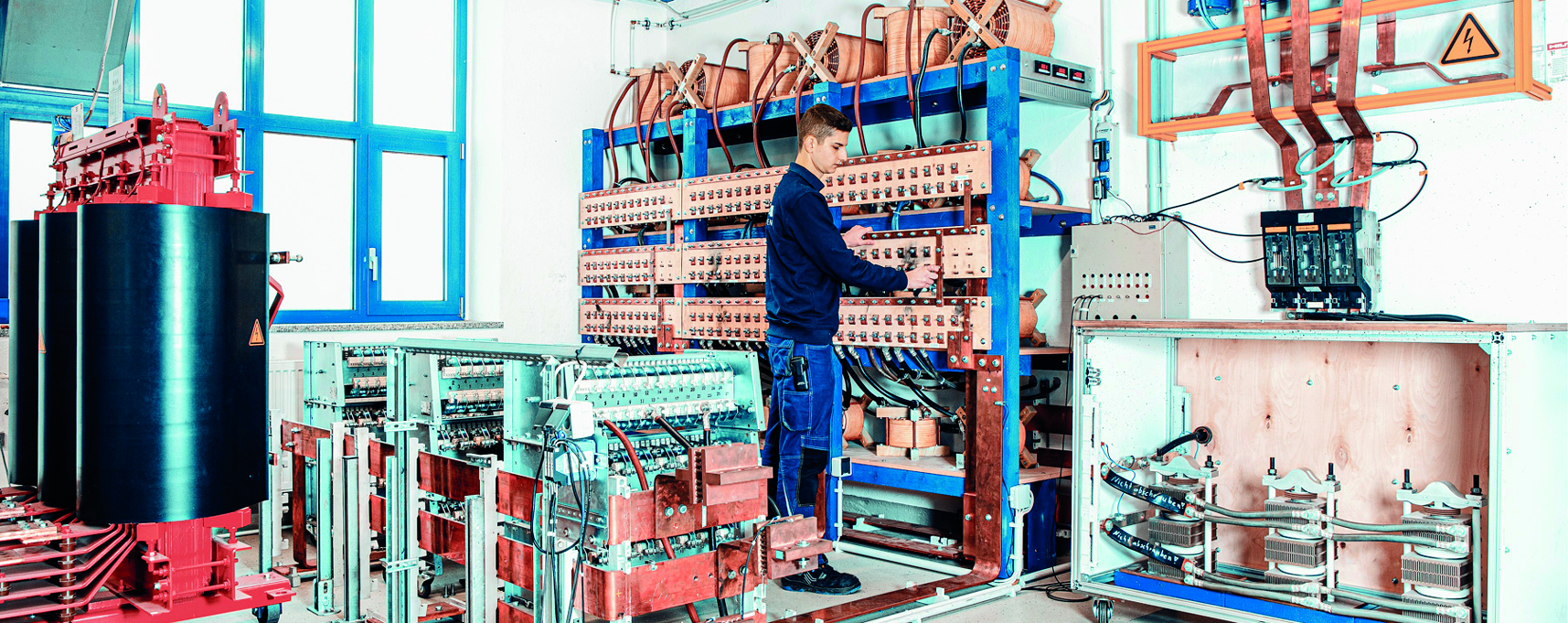

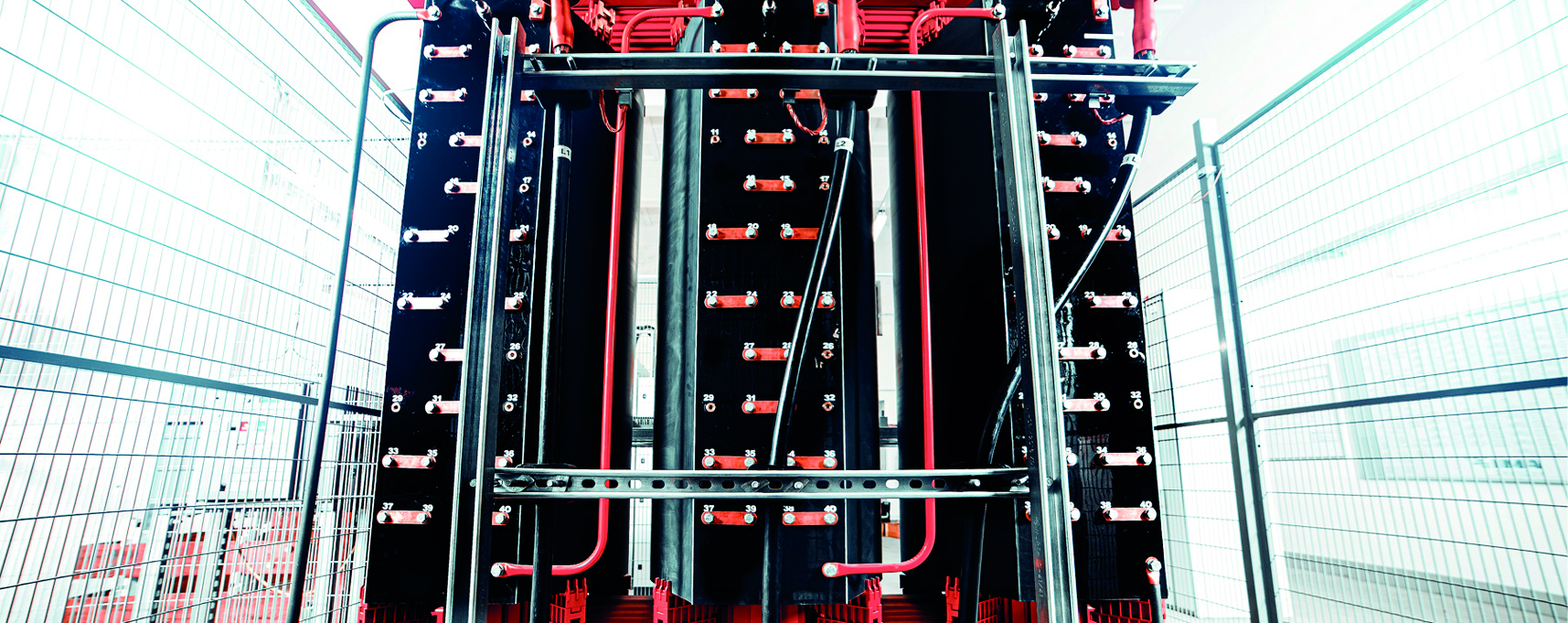

High-performance testing

In the high-performance test field, we test electrotechnical components and systems with regard to their short-circuit behavior, switching capacity and electrical service life. This enables us to ensure and evaluate the electrical functionality of components and assemblies.

With its in-house transformers, IMA Dresden can offer testing services with test currents of up to 25.000 A alternating current at 1.000 V and 30.000 A direct current at 1.300 V.

Testing in the high-power test laboratory

Products

- Power, load-break and transfer switches

- Switch-fuse units

- Contractors and motor-starters

- High-current components for the automobile industry

- Terminal blocks and connections

- Switchgear combinations

- DC fuses and relays

- cell connectors

- Battery management systems

- Battery disconnection systems (e.g. Pyrofuses)

Performance overview

| Switching capacity Operating performance Electrical endurance | Short-circuit | |

| Testing voltage | Test current | Test current |

| AC up to 800 V | up to 15,000 A | up to 60,000 A* |

| DC up to 110 V | up to 15,000 A | up to 60,000 A* |

| Load | ohmic, inductive ohmic, inductive | ohmic, iducive ohmic, inductive |

*up to 1 s protected by fuses or another protective device

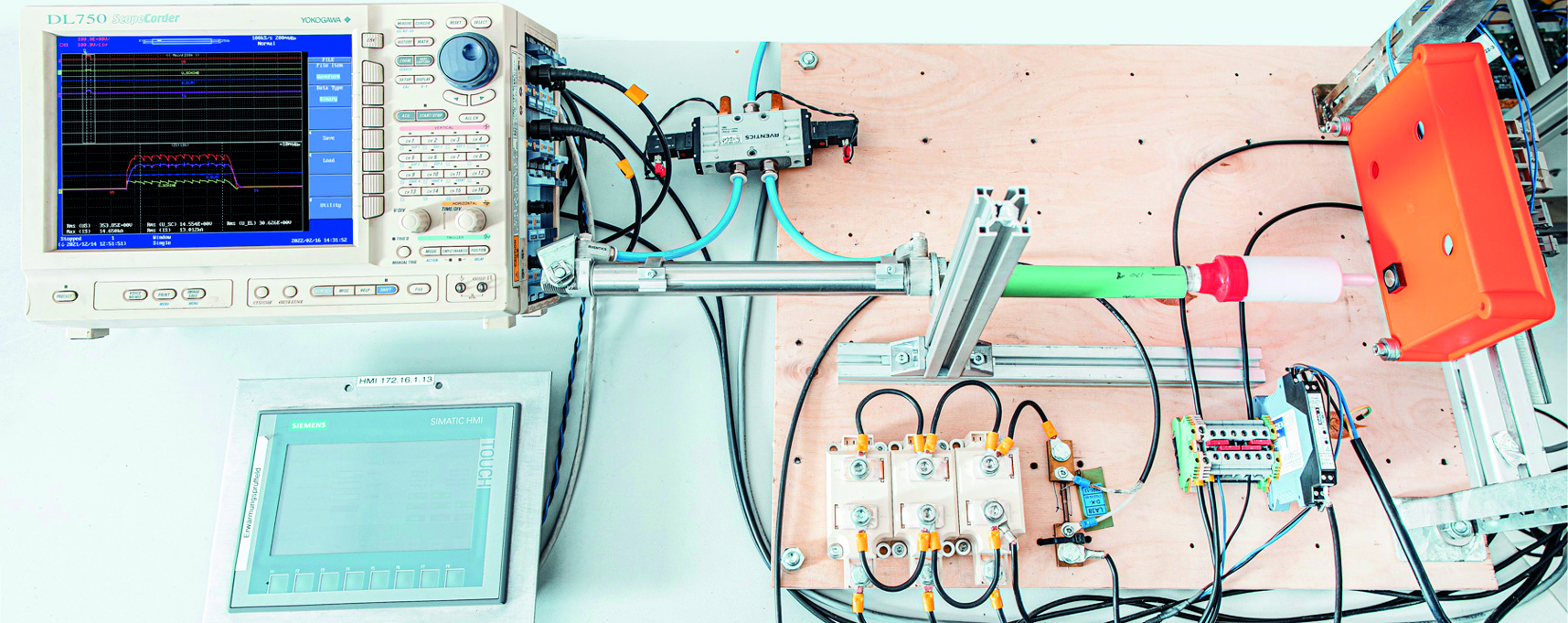

Electrical Lifetime testing

For electrically, pneumatically and manually operated switchgear, we have flexibly deployable test bays to respond quickly, reliably and cost-effectively to the different requirements for testing electrical / mechanical service life .

Products

- Control devices, proximity switches, signalling switches

- Relays, motor starters

- Switch-fuse units

- Contactor

Performance overview

| Testing voltage | Test power | Test current |

| AC up to 0–1,000 V | 140 kVA | up to 200 A |

| DC up to 1,300 V | 140 kVA | up to 200 A |

| Load | ohmic, inductive ohmic, inductive | ohmic, inductive ohmic, inductive |

Heating and continuous current testing

Heating tests on electrical equipment and switchgear are used for the thermal dimensioning of contacts, current paths and their supporting components made of insulating material. Furthermore, it is to be proven that the permissible limit values are complied with according to national and international standards.

The automated laboratory offers versatile testing possibilities for switchgear and switchgear assemblies:

- Continuous data collection for

- Temperature

- Electricity

- Voltage (determination of partial and total power loss)

- Voltage drops/contact resistance

- Cyclical electricity control (intervals/cycles)

- Overlay with climate tests and vibration tests

Typical tests

- Heating and continuous current testing

- Proof of ageing resistance

- Overload tests of devices with fuses and thermal trips

- Determination of derating curves (electricity can be adjusted to target temperature, e.g. connection area)

Typical device groups

- Terminal blocks and circuit points

- Heavy-duty connectors

Performance overview

| Alternating current* | 3-phase up to 2,000 A 1-phase up to 5,000 A | regulated |

| Direct current** | up to 4,000 A | regulated |

* testing at low voltage ≤ 5 V

** testing at low voltage ≤ 10 V

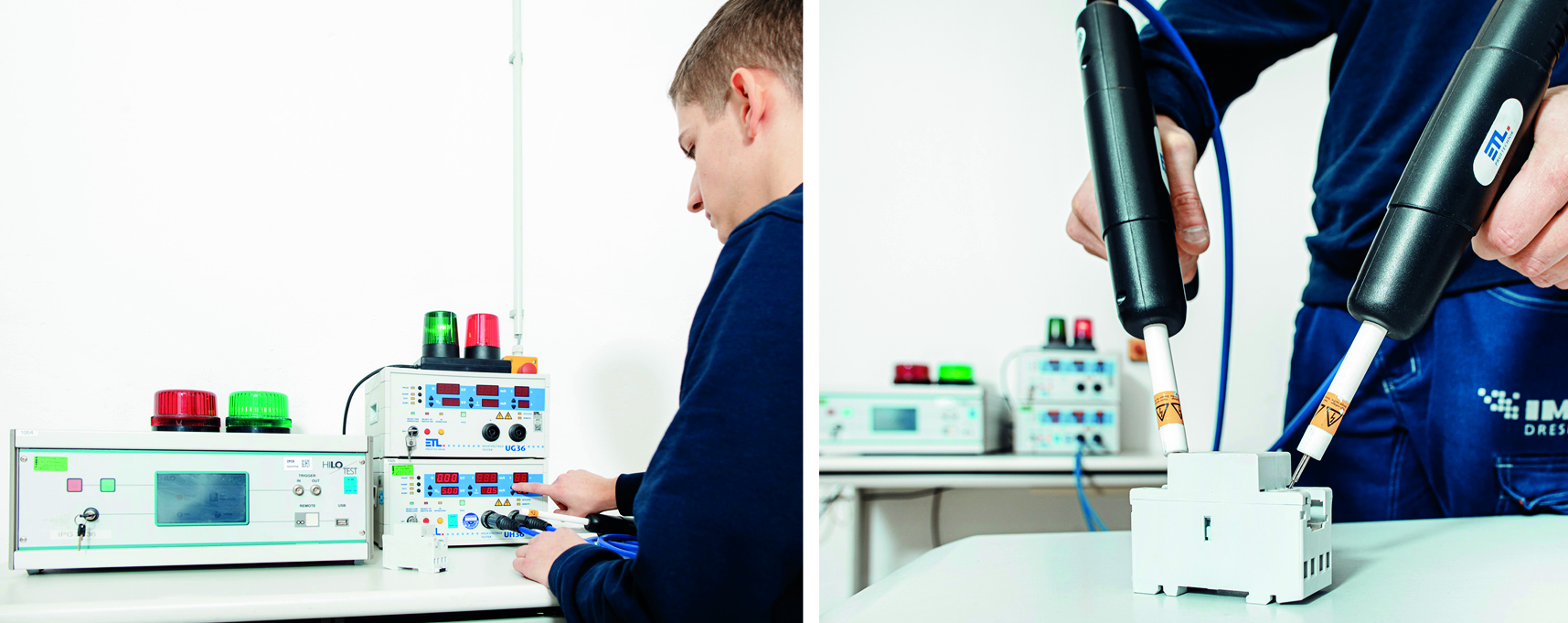

Insulation testing

Insulation tests are used to assess the functionality and safety of electrical devices and systems. Furthermore, insulating materials and constructive insulation solutions can be assessed.

Test methods

- Measurement of operating-frequency dielectric strength up to 5 kV AC

- Measurement of the operating-frequency dielectric strength up to 6 kV DC

- Impulse withstand voltage measurement up to 24 kV; 1.2µs/50µs (36 joules)

Other testing Options

- IP protection class tests

- Impact resistance test (IK code)

- Environmental simulation in the salt spray chamber

- Climatic tests (temperature and humidity), can be combined with other tests

- Vibration and shock testing

- Material tests of plastics and metals

- Strength of operating parts, e.g. in case of misuse forces

- Mechanical strength of clamping points

- Bending test

- Tensile test

- Creep and clearance testing

- Glow wire test and flammability