Trainings and Seminars to improve your strength and test performance

Straddling the fields of industry and research, our engineers build on knowledge that has grown through decades of extensive interdisciplinary practice and development. Theoretical or experimental proofs of strength are one of our core concerns. Demonstrating the reliability and safety of the material for the whole life of the component is a challenging task for computation engineers, designers and testers.

Benefit from our cross-industry expertise: in training sessions and seminars at your premises or at our offices, you will receive comprehensive specialist knowledge and concrete application recommendations

On this page you will find information about the following IMA training sessions:

- Aviation-specific courses for non-destructive testing (NDT)

- Applying the FKM guideline on “Analytical strength assessement of machine components”

- Training FE Simulation & FKM Guideline – WIAM® fatigue RIFEST in everyday engineering work

Our portfolio

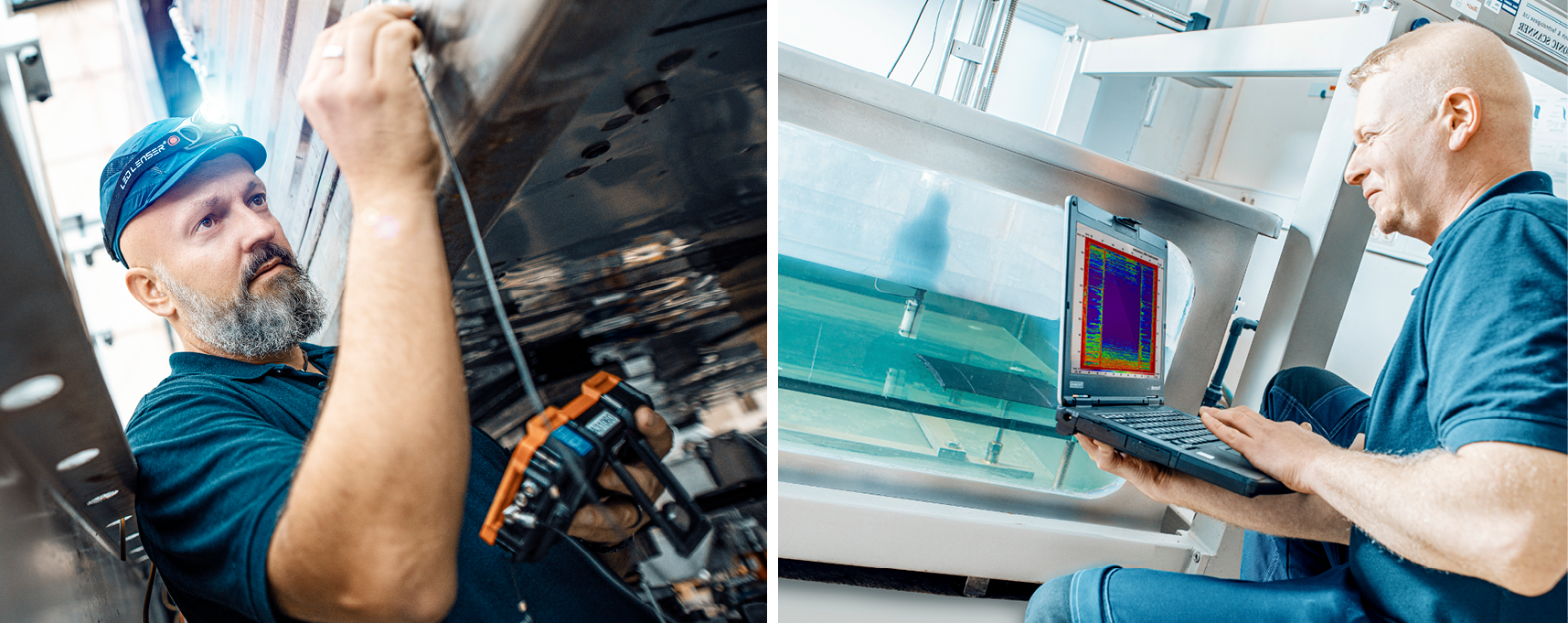

Aviation-specific non-destructive testing training courses

The NDT Training Centre holds training courses on non-destructive testing at its technology site in Dresden and is set to embark on a collaborative partnership with EFW Elbe Flugzeugwerke GmbH and IMA Materialforschung und Anwendungstechnik GmbH.

EFW Dresden is recognised by NANDTB Germany as a provider of NDT training and testing. It meets the requirements of EASA AMC 145.A.30(f).

Those attending the course will benefit from IMA Dresden’s many years of experience in materials and testing, coupled with the EFW’s expertise in aircraft conversion, maintenance and lightweight design. Together with exciting insights into aircraft conversion and work with actual testing techniques, the training will cover the latest test procedures. The trainers have extensive experience and technical expertise in this area.

It is worth highlighting that aviation-related information is based on the materials plans of the NANDTB, while the training is focused on future-oriented topics: the requirements of a maintenance company and specific aspects of component testing, knowledge of materials and approval tests. Another plus is that new developments in aviation, such as manufacturing processes, materials and test methods, are continually being incorporated.

The Training Centre offers the following courses:

- ET1 Eddy current testing level 1

- ET2 Eddy current testing level 2

- UT1 Ultrasonic testing level 1

- UT2 Ultrasonic testing level 2

- PAUT Ultraschall Phases Array

The courses comply with DIN EN4179 and NAS 410, while the NDT training is accredited by NANDTB Germany and meets the EASA AMC 145.A.30(f) requirements.

Training Programme 2024

| Dates | Training | Level |

| 04.12. – 21.12.2023 | Eddy current testing | 2 |

| 15.01. – 23.01.2024 | Eddy current testing | 1 |

| 05.02. – 08.02.2024 | Ultrasonic testing // refresher | 2 |

| 04.03. – 07.03.2024 | Eddy current testing // refresher | 2 |

| 18.03. – 26.03.2024 | Ultrasonic testing | 1 |

| 22.05. – 31.05.2024 | Ultrasonic testing | 2 |

| 06.06. – 14.06.2024 | Eddy current testing | 2 |

| 24.06. – 02.07.2024 | Eddy current testing | 1 |

| 02.09. – 05.09.2024 | Ultrasonic testing // refresher | 2 |

| 16.09. – 19.09.2024 | Eddy current testing // refresher | 2 |

| 21.10. – 29.10.2024 | Ultrasonic testing | 1 |

| 05.11. – 14.11.2024 | Ultrasonic testing | 2 |

| 02.12. – 10.12.2024 | Eddy current testing | 2 |

NANDTB Accreditation Elbe Flugzeugwerke

The FKM guidelines in practice

The FKM guideline “Analytical strength assessment of machine components” applies to mechanical engineering and related fields of industry and allows analytical strength assessement based on nominal stresses and local elastic stresses, taking all of the relevant influences into account.

It is published by Forschungskuratorium Maschinenbau e.V. (FKM) and is currently in it’s 7th edition, which was released in November 2020. As the guideline was issued under the leadership of IMA Materialforschung und Anwendungstechnik GmbH, you can get first-hand information at our seminar.

The aim of the seminar is to get acquainted with methodology and background of the analytical strength assessment according to FKM guideline. Find out more about:

- the uniformly structured, analytical algorithm consisting of instructions, formulae, tables and diagrams

- the static strength assessment and fatigue strength assessment, the latter depending on stress-time characteristics of constant amplitudes or variable amplitudes

- the scope of application for special materials such as steel, cast iron and aluminium alloys

- the application for components manufactured with or without machining or with welding

- the evaluation of nominal stresses and local, elastically determined stresses from analytical calculations, finite element analysis or measurement

The structure of the training

1. Introduction to the FKM guideline

- Basic information on stress types and strength assessment

- Scope of application, legal status

- Basic philosophy and structure of the FKM guideline

2. Static strength assessment for non-welded components

- Calculation of equivalent stresses

- Material properties and technological size factor

- Plasticizing reserve of the component

- Safety factors and degree of utilization

- Examples

3. Fatigue strength assessment for non-welded components

- Characteristic stress values

- Material fatigue strength

- Consideration of component properties using the design factor

- Consideration of the mean-stress influence

- S-N-curve and variable-amplitude fatigue strength

- Safety factors and degree of utilization

- Examples

4. Welded components

- Determination of assessment stresses for welded components

- Special features in static strength assessment: weld-seam factor, softening factor

- Special features in fatigue strength assessment: FAT classes, thickness influence, residual stresses, S-N-curve systems

- Examples

5. Procurement of input values for the strength verification

- Fatigue strength assessment: Processing of measured stresses via Rainflow counting and

mean-stress evaluation for fatigue strength assessment with equivalent stresses - Notes on the experimental determination of fatigue strength values

6. Individual training focal points

- special areas of application, materials, sector-specific regulations

Dates

Online courses in English (4 days each 4 hours / 1,390.00 € per person)

- 13.05.2024 – 16.05.2024

- 25.11.2024 – 28.11.2024

The seminar is offered individually at our offices in Dresden, at your premises or as online seminar.

For more information on possible dates and terms, please contact us. We will be glad to make you an offer suited to your needs.

Registration and contact

|

Dr. Tom Schiemann Phone: +49 (0)351 8837-6565 |

Training FE Simulation & FKM Guideline –

Wiam® fatigue RIFEST in everyday engineering work

The application of the FKM-guideline ” Analytical strength assessment for machine components ” and the determination of the input variable in practice.

The guideline is a work published by the Forschungskuratorium Maschinenbau e.V. (FKM) for the analytical strength assessment of machine components. It contains a uniformly structured calculation algorithm for all applications. The current 7th edition (published in December 2020) has already been implemented in Wiam® fatigue RIFEST.

The practical application of the guideline in everyday engineering presents many challenges. Starting with the modeling in the FE model, determination of input variables up to the interpretation of the results. This seminar gives an insight into these problems by means of practical examples. The aim is to enable the engineer to apply the guideline confidently in everyday tasks. The strength checks are carried out in the seminar using the WIAM® fatigue Rifest software, which enables a method-assured check in accordance with the FKM guideline.

Target group

Every engineer for whom a safe practical application of the FKM guideline “Analytical strength assessment for machine components” is necessary on a day-to-day basis.

Benefit

- Safe FE modeling for unwelded and welded components

- Determination of necessary input data for the FKM- guideline (plastic form number, collectives)

- Interpretation of the results

Basics

Basic skills in calculation with the FKM guideline are a prerequisite. The FE modeling is carried out exemplarily with Ansys®Workbench (no software training).

The structure of the one-day training

1. Introduction to WIAM® fatigue Rifest

- Introduction / General Overview

- Program content

- Program content

- Classification of the program content

- Program implementation

2. Unwelded components

Determination of input variables for the assessment

- FE model formation

- Determination of the necessary stress parameters

- Determination of the stress gradient

- Determination of the plastic form number with the help of the FE model

Strength assessment with Rifest

- Execution and evaluation of the static strength assessment

- Execution and evaluation of the fatigue strength assessment

3. Welded components

Determination of input variables for the assessment

- FE modeling for different assessment concepts

- nominal stress concept/structural stress concept

- Notch stress concept

- Effective stress concept

- Determination of the necessary stress parameters

- Determination of the plastic form number with the help of the FE model

Strength assessment with Rifest

- Execution and evaluation of the static strength assessment

- Execution and evaluation of the fatigue strength assessment

4. Determination of collectives on the basis of measurement data

- Creation of the rain flow matrix

- Creation of stress collectives

- Operational strength assessment

5. Use of own material data

- Use of own material data in the strength assessment

6. Discussion of customer examples

- Discussion of own examples occurring in practice

Date/cost

Online courses in English (4 days each 4 hours / 700.00 € per person)

- 17.05.2024

- 29.11.2024

The seminar is offered individually both at our offices in Dresden, at your premises or as online seminar.

For more information on possible dates and terms, please get in touch.

Registration and contact

|

Dr. Tom Schiemann Phone: +49 (0)351 8837-6565 |

PARTICIPANT NOTE

In combination with the 2-day basic training on FKM training, you will receive a 20% discount on this seminar.

In order for you to be able to practically reproduce the examples presented with the help of WIAM®fatigue Rifest, we offer you the possibility to test the software free of charge for 1 month.