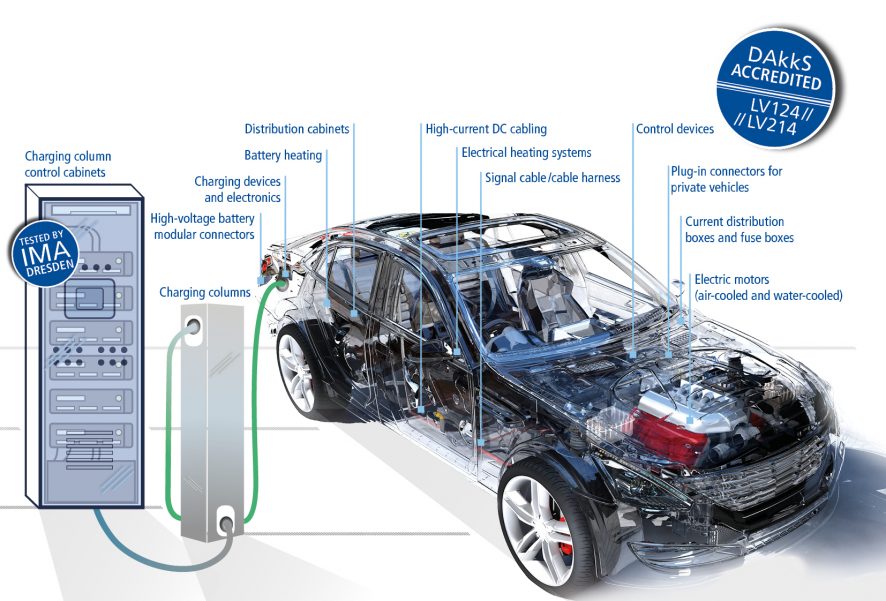

Electrical testing in the field of automotive

The modern form of locomotion – electromobility – requires new approaches in research and development but also in testing.

The requirement for quality, safety and reliability are nevertheless paramount.

And this is exactly where IMA Dresden’s expertise comes in with its testing services.

The comprehensive test spectrum ranges from individual tests to complete validation of electrical components for almost every vehicle type and comprehensive load units.

Our advantage: Complete design and product validation from a single source.

Our portfolio

LV 124 / LV 214 / LV 123 / LV 148 / LV 215 – ACCREDITED TESTS

In the broad field of electromobility, the LV 124 and LV 214 standards are the most important ones to be met. The topic of electromobility does not have to be limited exclusively to the automotive industry; the rail vehicle and aviation sectors are also increasingly moving toward alternative drive concepts.

LV 124 was compiled by representatives of leading automotive manufacturers such as Audi AG, BMW AG, Volkswagen AG, Porsche AG, etc. and describes various electrical tests and their requirements that can be performed in our laboratories.

Scope of testing according to LV 124

- Part I – Electrical requirements and tests 12 V electrical system

- Electrical requirements and tests

- Part II – Environmental requirements and tests

- Mechanical requirements and tests

- Climatic requirements and tests

- Chemical requirements and tests

- Durability tests

Testing

- Current distribution boxes and fuse boxes

- Plug-in connectors for vehicles

- Automotive fuses

- Charging devices and electronics

- Battery heating

- Distribution cabinets

- High-current DC cabling

- Electrical heating systems

- Signal cable / cable harness

- Control devices

- Electrical drives

- Distributor cabinets for charging stations

Tests in the field of electromobility

In accordance to your requirements we perform a large variety of electrical tests and environmental simulations in our labs. No matter whether for a standard test, a special solution or a combination of overlay of several test units. We are also your partner when it comes to tests of the current profiles, the lifetime or an environmental test superimposed with a mechanical test.

Current test

- Continuous currents up to 10,000 A DC (power distribution)

- Current profiles: More than 500 electronically controllable resistors to simulate loads

- derating tests

- Continuous measurement data acquisition of current, voltage and temperature over the entire test period (> 1.000 measurement channels, sampling rate 1/s)

Switching test / current carrying capacity

- High-performance test field with phase angle control

- Short-circuit test up to 000 AAC / 30.000 ADC (Battery cell connector)

- Test voltages up to 000 VAC and 1.300 VDC

- Hotspot detection with thermal camera

Lifetime testing

- The test bay is designed for electrically, pneumatically and manually operated switchgear

- Testing of electrical/mechanical life

- Testing of the operating behavior

- Testing of the making and breaking capacity

Typical device groups

- Control units, proximity switches, signaling switches

- Relays, motor starters

- Switch-fuse units

- contactors

Medium-conducting Systems

- Complete cycles, fuel lines, coolant etc.

- Slosh test on the fuel tank system

- Leak testing/pressure pulse

- Chemical testing

Vibration and shock testing/Multiaxial vibration test

- Free fall

- Vibration

- Mechanical shock

- MAST testing

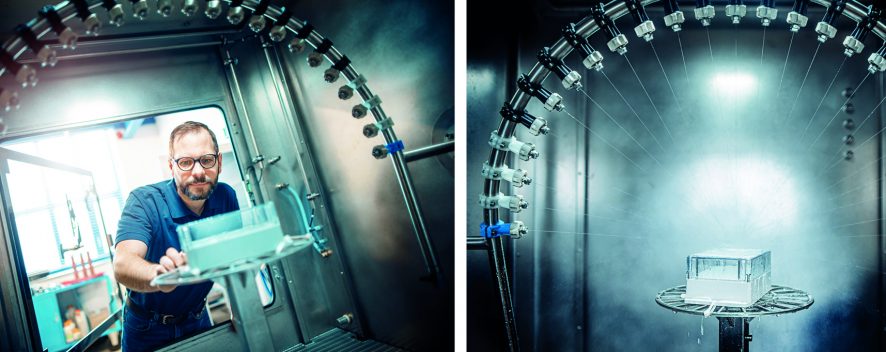

Climatic testing

- High/low temperature storage

- Temperature level test

- Temperature shock

- Humid heat , cyclical (with frost)

- Lowtemperature service

- Dipping bath installations

- Temperature shock chambers

IP protection class testing

- Saline fog

- Dust test

- Corrosion sun

- Lifetime

- Simulate real operating conditions

Testing standards

- LV 123 electrical characteristics and electrical safety of high-voltage in vehicles

- LV 124 electric and electronic components for vehicles uo tp 3,5t

- LV 148 electric and electronic components in vehicles with 48V board network, test conditions and tests

- LV 214 connectors for vehicles

- LV 215 High-voltage connectors for the requirements in vehicles